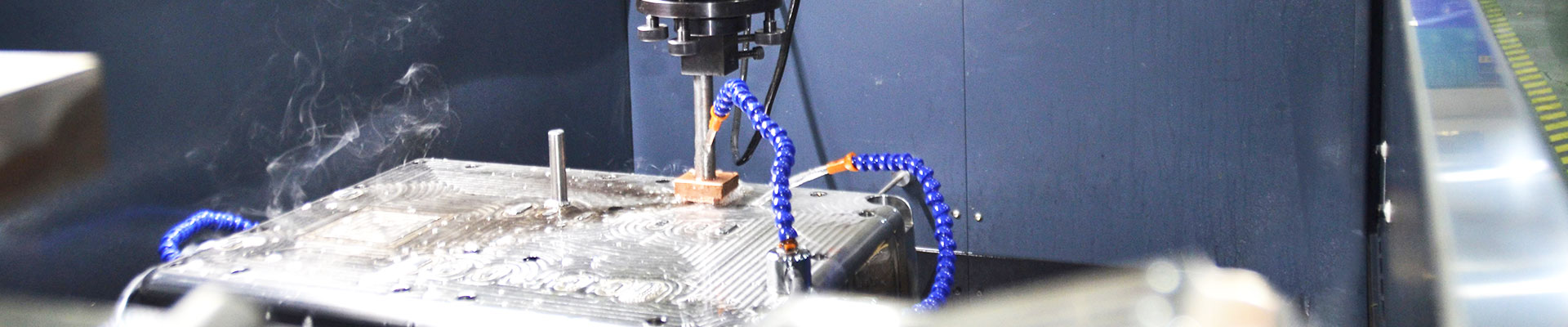

CNC turning service

When you need precision-turned parts, Shbury is ready to help. We’re machining specialists with a focus on CNC turning of complex geometries and tight tolerances in challenging materials.

Shbury provides excellent quality CNC lathe services United States and Europe based on the requirements to customers, featuring precision machined parts, lathe parts. Our precision CNC Turning Parts applications exist in a variety of industries including automobile, electronics, medical and more. We mainly serve customers from the United States, Europe, the Middle East, and more countries & regions.

Contact Us

Our CNC Turning Capabilities

| Machine Capacities | We have an extensive line of CNC lathes, vertical machining centers and horizontal machining centers. Our automatic bar-feeders can accommodate bar stock up to 4 inches or 101.6 (mm) and our hand-loaded chucking lathes can hold machined parts up to 16 inches & 406.4 (mm) in diameter. Our Verticle machining centers can machine parts that are up to 20 inches, (508 mm) cubed, while our Horizontal machining centers can machine parts that are up to 30 inches (762 mm)cubed. |

| Raw Materials | Steel, Stainless steel, Aluminum, Brass, Bronze, Plastics, Extrusions as well as cast/extruded Tubing from practically any raw material. We also machine sand castings, permanent mold castings, forgings and extrusions as well. |

| Industries Served | Fiber Optic, Hydraulics, Industrial Applications, Agriculture, Motorcycles, Pumps, Medical components for carts/beds, Oil & Gas industry, Appliance industry, Motor sports, Mining, RV Industry, Truck/Off-highway components, Safety components, Transmission components, Lift Trucks, Recreational Vehicles, Industrial Packaging, HVAC & many others. |

| Common Applications | Almost anything. Hydraulic components, water fittings, oil fittings, valve components, air brake components, pump components, truck steer components and many others. |

| Turnkey Line Ready Parts | We delivering Tier one Line ready parts requiring almost any secondary operation including, heat treating, plating, grinding, honing, broaching, balancing, splining, painting, plating & assemblies. |

|

Quality |

ISO 9001:2015 Certified & ITAR Registered. |

|

Tolerances for CNC Turning |

± 0.005″(metal)/±0.05″(plastic) |

-

CNC Turning Metals Services

-

CNC Turning Plastics Services

-

Turned Part Polishing Services

Difference Between CNC Milling and Turning

CNC Milling and CNC Turning allow users to create patterns and add detail to metals that are impossible to do by hand. CNC Milling uses commands, codes programmed into the computer and set to run. The mill then drills and turns along axes to cut materials to dimensions entered into the computer. Computer programming allows machines to make precise cuts, users can manually override the CNC Machines to slow or speed up the process.In contrast, CNC Turning uses computer-controlled machines to create a different final product. The process uses a single-point cutting tool that inserts parallel to the material to cut. The material is rotated at changing speeds and the tool cutting traverses to create cylindrical cuts with exact measurements. It is used to create circular or tubular shares from larger material pieces. It is an automated process and speeds can be adjustments for greater accuracy rather than turning a lathe by hand.

If you’re not sure if your part should be best produced by Turning or Milling, call our experts, we’ll go over the project and recommend the best process for your project.

-

CNC Milling

-

CNC Turning

Why Take Shbury To Your Trusted CNC Lathe Machining Services Supplier?

First, as a CNC machining supplier in China, we have our in-house machines including several automotive lathes. Among them, some are high precision lath machines imported from Japan, so we can make high-precision milled parts for our customers according to your drawing and specification.At the same time, we have an experienced team of CNC turning operators. They can run precise lathe machining well to build your part with a beautiful surface. Thus, you don’t need another polishing process to remove the visible tool mark, this can you for a cost-saving.

Thirdly, our design engineers had handled thousands of turned part projects. They have so much manufacturing experience that can help you by recommending some good design tips, this might lead to another big cost-saving for your project.

Also, we can handle a full range of engineer materials, covering both plastic material and metal material. Among them, aluminum turning is one of our key services, we can create aluminum turned parts with high quality at a reasonable price.

In advance, we offer a one-stop solution. Besides the CNC turnings process, we also support other process services such as prototyping, low-volume manufacturing, finishing, assembly. Therefore, we are sure that you can get quality parts for up to 30% less than other competitors.

At Shbury, there are no limits to quantity. Whether you need a single prototype part, low-volume production, or production order, we can make it.

In a word, RapidDone is the right lathe machining company you should choose. We are glad to support you, helping you make the right solution for a turning project. We will give you the most professional CNC turning service once you have a project for us.

Let Shbury Quote Your Project

We can quote your job using conventional CAD files, fill out our simple form and we will contact you with a competitive quote. Shbury, is constantly striving to improve and optimize our processes and maximize customer convenience. Our customers range from inventors to businesses to government agencies. We are focused on quality and customer service.