CNC Machining Services

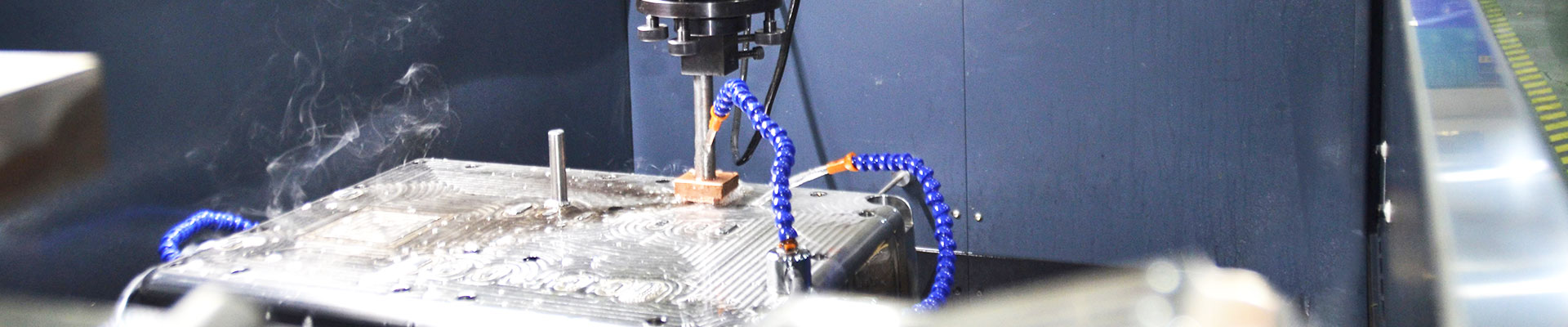

Whether you need 1 prototype part or low volume production parts, our CNC machining department has you covered. Our custom CNC Machining services include the ability to meet precision tolerances as tight as ± 0.0001″.

ONE-STOP MANUFACTURING SERVICE

We have posted videos related to corporate presentations on YouTube, click on the link to learn about:

https://www.youtube.com/watch?v=D6KHwabHrRA&t=32s

As a long-tenured company in the manufacturing industry, we at Shbury. are expert providers of custom CNC machined components. Over the last ten decades, we have continued to expand our capabilities and invest in the newest technology and equipment to better serve our customers. Our CNC capabilities allow us to fulfill a broad range of product requirements in a prompt, quality-driven, and cost-effective manner.

With 5-axis capabilities and customized programming tools, we can machine all features of a workpiece from a single setup at accelerated cycle times. Also included in our CNC machining arsenal is an automated pallet changing system that allows for continuous machining. Consequently, no idle time means faster throughput and quicker turnaround. All of our processes are quality-certified, and we employ statistical process controls to monitor accuracy, minimize variability, and produce a consistently high rate of conforming product.

We machine metals in a variety of grades and temper, including stainless steel, aluminum, aircraft alloys, copper, and many more. Our team of skilled professionals can design and build dedicated work holding fixtures as well as custom product fixturing solutions to promote repeatable production. In addition to milling, drilling, and boring; we can create complex thread profiles, and internal forms on workpieces that measure up to 80.0” in length x 20.0” in height 30.0” wide. As a full-service manufacturer, we also offer additional services, such as grinding, heat treating, and metal finishing.

Whether you need prototype parts or a production run on a large scale, we have the resources to meet your needs. We are an ISO 9001 certified company and capable of meeting a range of tough industry standards. For more information about our CNC machining capabilities or a quote, contact us today.

Shbury Different Types of CNC Machining service

Shbury supports various CNC Machining fabrication methods such as 3, 4 and 5 Axis Milling as well as Turning and other methods. See below to learn more.

Precision CNC Machining Capabilities

- Machining Processes

-

-

Milling

Drilling

Boring

Turning- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

-

Threading (Single Point)

- External

- Internal

Counterboring

Countersinking

Facing

Broaching

-

Milling

- Equipment Capabilities

-

-

CNC Control Capabilities

Horizontal Machining Centers

Vertical Machining Centers

Horizontal Turning Centers -

Vertical Twin Spindle Turning Centers

Multi-Task Lathe/Mill (Dual Turning & Milling Spindle)

-

CNC Control Capabilities

- Machinery Axis

- 3, 4, 5

- Fixturing

-

-

In-House Fixturing & Tooling

Three-Jaw Chuck

Twin Pallets

-

Automated Spindle

Tool Changer

Robotic Load / Unload (Pick & Place)

-

In-House Fixturing & Tooling

- Materials Used

-

-

Gray Iron

Ductile Iron

Aluminum

Stainless Steel

Steel

Brass -

Cast Iron

Forged Alloy

Tin

Nickel

Plastics

Copper

-

Gray Iron

- Turning Diameter

- Up to 31.5 in.

- Milling Length (X)

- Up to 59.8 in.

- Milling Width (Y)

- Up to 31.5 in.

- Milling Height (Z)

- Up to 32 in.

- Maximum Part Weight

- 2,000 lbs.

- Tolerance

- ± .0002 in.

- Process Capability

- ≥ 1.33

- Process Performance

- Ppk ≥ 1.67

- Secondary Services Offered

-

-

Engineering

Deburring

Broaching

Welding

Painting

Plating

Assembly

Packaging -

Logistics and Scheduling

Transportation Routes

Inventory Management

Paperwork Reduction

Advanced Shipping Notices (ASN)

Barcoding

Warehousing

-

Engineering

- Testing

- Dimensional

- Inspection

-

100% Layout

1st Piece Inspections

In-Process Verifications

- Process Manuals

-

Production Part Approval Process (PPAP)

Advanced Product Quality Planning (APQP)

Statistical Process Control (SPC)

- Quality Control

-

Coordinate Measuring Machines (CMM)

Automatic Tip / Probe Changer

Calibrated Measuring Instruments and Gages

- Production Volume

- Prototype to Production

- Lead Times Available

-

2-7 days for samples

7-15 days for production

- Delivery

- 99.8% On-Time

- Supply Chain Management

-

KanBan

Inventory Management / Stocking Program

Supplier and Process Management

Shbury Materials

| Aluminum | Bronze/Brass | Copper | Plastics | Steel / Titanium / Zinc |

|---|---|---|---|---|

| AluAL6061 | HPb63 | C11000 | ABS | Stainless Steel 303, 304, 316/316L |

| AL6063 | HPb62 | C12000 | PC | Stainless Steel 15-5, 17-4PH, 18-8 |

| AAL7075 | HP59 | C18000 | Acrylic | Stainless Steel 416, 420 |

| AL6082 | H62 | C36000 | POM/ Delrin | Titanium Grade 2, Titanium 6Al-4V |

| AL2024 | H68 | Nylon | 4140/4340/1010/1020/A36/D2/C45/Q235/Q345 | |

| AL5052 | Aluminium Bronze | PVC | ||

| PEEK | ||||

| G-10 Garolite | ||||

Additional alloys and tempers are available upon request. We can source to your project specifications.

Additional Information

- Industries Served

-

-

Transportation

Medium & Heavy Trucking

Automotive

Commercial Vehicles -

Energy

Food Processing Equipment

Hydraulics

Gas Compression

-

Transportation

- Intended Applications

-

-

Wheel Hubs

Cylinders

Rotors

Brake Calipers

Rotary Compressors

Reciprocating Compressors -

Power Generation / Distribution

Motor Housings

Wheels

Pulleys

Pistons

Industrial Food Equipment

-

Wheel Hubs

- Industry Standards Met

-

ISO 9001:2015 Certified

TS 16949:2009 Certified

- Software Utilized

-

-

SolidWorks

Vericut ToolPath

MasterCAM

QC-Calc (SPC) -

CMM Manager

OpenDMIS

Adobe PDF

Images (JPG, GIF, TIFF, BMP)

-

SolidWorks

CNC Machined Parts We Offered

We use advanced equipment and have a team of experienced professionals who are committed to producing precision parts

to meet your exact specifications.

to meet your exact specifications.

Benefits of Partnering with us for machining

- Our machining facilities produce machined components for almost every industry there is using virtually any raw material you can imagine. Some of the raw materials include steel, stainless steel, Brass, Aluminum, Bronze, bar stock, sand castings, investment castings, permanent mold castings, steel forgings, aluminum forgings, drawn tubing, cast tubing, bar stock from almost any alloy as well as plastic materials. Volumes range from prototypes to start-up quantities into low volume as well as full production quantities of thousands of pieces, tens of thousands of pieces, or even tens of millions of pieces.

- We assist our customers by providing the Lowest Total Cost machining processes and equipment available to manufacture each required machined part. The design of the part, tolerance requirements, the size of the part as well as the EAU (Estimated Annual Usage) are the key driving factors that determine what type of machine is the best fit for each component. Whether you are requiring an extremely small .006 hole drilled using a CNC Swiss machine for a medical component or a 16" diameter bar stock component used on a Military vehicle, an ultra high volume complex machined part requiring Hydromat or Buffoli machines a high volume Multiple-Spindle component for the automotive or appliance industry or low to medium volume turnkey fully machined castings or forgings. Our custom machining services have you covered.

- Different types of machines provide different core competencies. The wide variety of diverse equipment available at our machining facilities provides us many different ways to turn, drill, mill, hone, grind, broach, spline, and machine bar stock, castings, forgings as well as tubings and extrusions in almost any raw material.

- All of our machining facilities run two shifts 5 days per week but one of our facilities runs 3 shifts 24 hours per day 5 days per week.

- Our machining facilities have a combination of ISO 9001:2015 as well as AS9100 Certified.

- Our quality teams consistently do capability studies, gauge R&R's, SPC and keep inspection records. All of our facilities are equipped with the latest CMM's, vision systems, and various gauges required to inspect any part we produce as well as document all information that is required for ISIR and PPAP submissions.

- Our facilities average over 98% on-time deliveries to all of our customers.

- We have single and double-digit PPM numbers with our customers.

- Our facilities show and audit extremely well.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy