Vacuum Casting service

Shbury is fully capable of meeting your polyurethane vacuum casting needs. With many years of professional experience and advanced equipments, we could manufacture parts to meet your requirements, even exceed your expectations, and with fast turnarounds. Vacuum casting is a good method for manufacturing rigid or flexible parts, and is one of the ideal choices for prototype manufacturing, assembly testing, concept verification and Exhibition demonstration. These parts can be made from hundreds of casting polymers. Our vacuum casting service generally uses 3D printing or CNC machining to manufacture main mold and silicone mold. The precision of parts in vacuum casting depends on the main model, the geometric structure of parts and the casting materials. Usually, the predicted shrinkage rate is + 0.15%.

Why Choose Vacuum (Urethane) Casting

Vacuum Casting vs Plastic Injection Moulding

Vacuum casting produces parts with similar properties to plastic injection moulded parts. Injection moulding demands a higher front-end cost and a lower unit price, whereas vacuum casting offers a lower front-end cost with a higher unit price. This makes urethane casting a more cost-effective choice for developing early prototypes before creating end-use injection moulded parts.

Vacuum Casting is Used For

Low volume prototypes, low volume production, clear transparent parts, rubber parts, market testing, rapid iterations

Advantages of Vacuum Casting

- Great for low volumes

- Self-coloured parts

- Low upfront investment

- Production like parts

- Massive range of materials

Technical Specifications

1 Standard lead time: Up to 10 copies within 15 working days2 Standard accuracy : ±0.3% (with a lower limit on ± 0.3 mm on dimensions smaller than 100 mm)

3 Minimum wall thickness: To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm

4 Maximum part dimensions: The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters)

5 Typical quantities: Up to 25 copies per mold (depending on the mold’s complexity and the casting materials)

6 Surface structure: High-quality surface finish comparable to injection molding

Tolerances for Vacuum Casting

| Dimension | Tolerances |

|---|---|

| 0.5 – 6.00 mm | ± 0.10 mm |

| 6.00 – 30.00 mm | ± 0.20 mm |

| 30.00 – 120.00 mm | ± 0.30 mm |

| 120.00 – 400.00 mm | ± 0.50 mm |

| 400.00 – 1000.00 mm | ± 0.80 mm |

| Angular: ±0.5° | |

A shrinkage rate of 0.15 % is to be expected in general.

-

Vacuum Casting Parts

-

Vacuum Casting

-

Vacuum Casting

Advantages of Vacuum Casting

1, Fast turnaround

Shbury can provide up to 20 parts in 7 days or less, depending on part specification and volume.

2, Affordability

Silicone molds are less expensive than the tooling used for injection molding, resulting in low prices.

3, Capable of producing large parts

Depending on the type of equipment used, vacuum casting can to create very large parts.

4, Superior surface finish to injection molding

The vacuum process removes air bubbles and allows the material to capture fine details.

5, Color options

Coloring pigments can be added to the resin for a variety of color options.

6, Repeatability

Silicone molds can be used around 20 times before they need replacing.

The Difference Between CNC Prototyping And Vacuum Casting Prototyping

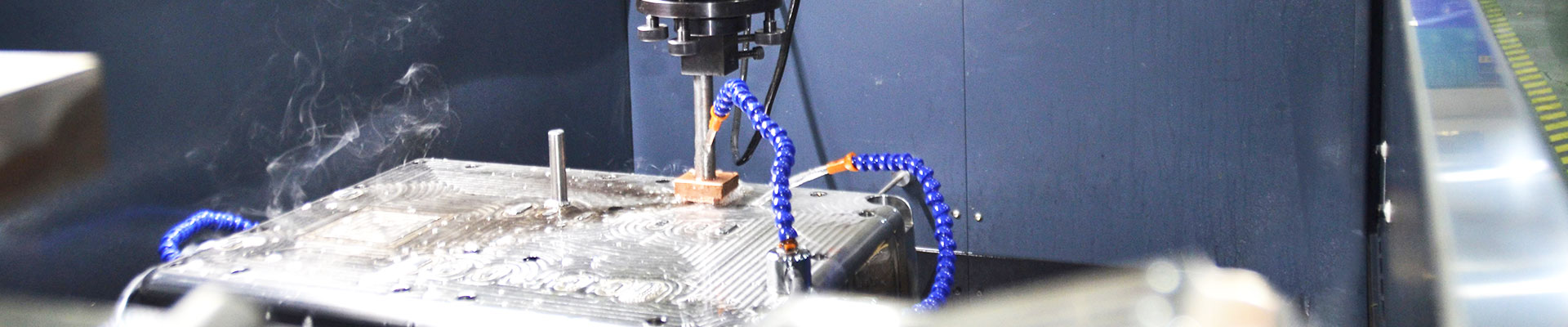

Both CNC machining and vacuum casting are ways to produce rapid prototypes. CNC machining refers to programming by CNC machining language. The cutter on the CNC equipment moves on the material according to the path set by the program, and cuts off excess material to obtain the prototypes of required shapes and sizes. Vacuum casting refers to making simple silicone molds through master patterns, and then replicating the parts. The cost of vacuum casting is low and the cycle is short. So what are the main difference between CNC prototyping and vacuum casting prototyping? Let's take a look bellow:

Materials are Different

The materials of CNC prototypes are extensive and can include plastic and metal. Plastic CNC prototyping materials include: ABS, acrylic, PP, PC, POM, nylon, PEI, PEEK, PBT, PTFE and other materials; Metal CNC prototyping materials include: aluminum, stainless steel, copper, steel, iron, etc. The range of materials used for vacuum casting prototypes is relatively narrow, mainly rubber, ABS, PC, PA, PP, and acrylic materials, etc.The Precision is Different

The precision of CNC machining prototypes will be much higher than the precision of vacuum casting prototypes. The precision of our CNC machining is generally between 0.02mm-0.05mm, while vacuum casting prototypes may be slightly deformed and shrunk due to thermal expansion and contraction, the accuracy is not so easy to control, generally is around 0.2mm. Therefore, in general, vacuum casting prototype does not have very strict requirements on precision.The Production Speed is Different

CNC machining requires machining step by step, while vacuum casting only needs to make a silicone mold and then replicate the component. Generally, a silicone mold can replicate about 8-15 parts, and the production speed is faster than CNC machining.The Cost is Different

Since the CNC machining prototyping needs to be machined step by step, and it takes a certain amount of time to adjust the machine, the cost of the CNC prototype is generally relatively high, while the vacuum casting prototyping can be one-piece forming produced via vacuum mold casting. Therefore, the production cost of Vacuum Casting will be much lower.

Typical Vacuum Casting Finishing Options

| Applicable Materials | Colors | Decsription | |

|---|---|---|---|

| Painting | All | Black, Pantone/RAL colours | Painting is a way to add colour, a great way to improve the aesthetics of vacuum casted parts. |

| Plating | ABS | Metallic | Plating is method of adding a thin layer of metal of the outer layer of a material. It is used to harden, decorate and improve wearability of parts. |

When is vacuum casting used?

Vacuum casting is suitable for prototype and end-use parts. It can be used for concept models, visual models, pre-production prototypes, functional test prototypes, models for thermal and air flow testing, and for assembly line trials.

For functional prototypes, vacuum casting is excellent for adding elastomeric sealing features to parts produced by other prototyping technologies, or for overmoulding metal components.

Polyurethane is sufficiently robust for end-use parts – for elastomeric seals, for example, or overmoulded ergonomic grips or complex geometries.

Vacuum casting is used in industries as diverse as Medical, Life Science, Automotive, Aerospace and general manufacturing.

Application of Vacuum Casting

Vacuum casting has a wide range of applications in various industrial fields, such as medical equipment, aviation, automotive industry, electronic products, etc. When you need a small quantity of production-quality plastic parts (from 10 to 50 sets), you should choose vacuum casting to avoid the long lead time and high cost of creating plastic injection mould tools.These parts are used in prototypes and display models to verify the fit and function of a new design. In some instances, vacuum casting can also be used for end-use parts. Because the casting polyurethane can simulate the properties of ABS, Nylon, PP, PMMA, and soft TPE rubber.