Sheet metal service

We are set up for Quantity 1 and Low Volume Production volumes up to 5,000 Parts

Shbury Service Highlights

- State-of-the-Art Laser/Punch Press Technology

- Automated Loaders for 24/7 Cutting Production

- Cutting Capabilities up to 0.25" Material Thickness

- Accurate Ram Systems Designed for Repeatability

- Forming Capabilities up to 10 Feet in Length

- 2D & 3D Scanning for Quality Assurance

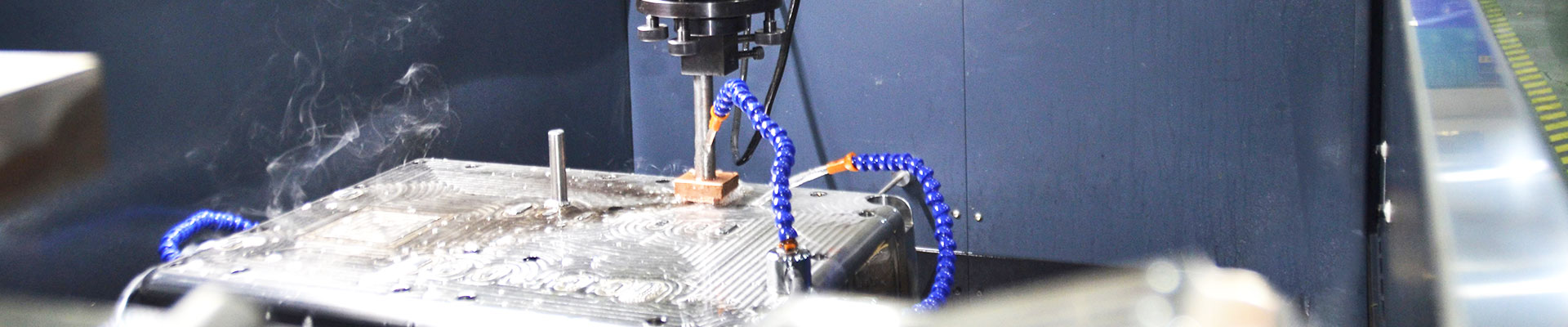

How to Fabricate Sheet Metal?

Generally, we can shape sheet metal by cutting or forming. Since there are various ways of cutting and forming, we use many specific tooling, which may drive up costs. If you know more about fabrication procedures, you can design your sheet metal parts more efficiently.Sheet metal typically comes in thicknesses ranging from 0.006 to 0.25 inches (0.015 to 0.635 centimeters). The fabrication begins with a flat sheet of metal. Your design files (3D files) show how to cut, form, and finish the sheet metal parts. We can cut and form the material and then join them together. We can make it into angel iron by bending, laser cutting, and bending the edges to make enclosure panels.

The metal sheet metal forming process is a widely used metal working technology that plastically deforms a thin metal sheet by an external step force, exceeding the material’s yield strength, bending and drawing into various complicated shapes without reducing the material itself. Metal sheet metal forming processes generally require the use of high quality molds to obtain the desired metal product.

-

Sheet Metal Part

-

Sheet Metal Parts

-

Sheet Metal Service

Popular Sheet Metal Materials

|

Aluminum |

Copper |

Steel |

|

Aluminum 5052 |

Copper 101 |

Stainless Steel 301 |

|

Aluminum 6061 |

Copper 260 (Brass) |

Stainless Steel 304 |

|

|

Copper C110 |

Stainless Steel 316/316L |

|

|

|

Steel, Low Carbon |

Sheet Metal Tolerances

|

Description |

Condition |

Tolerance Notes |

|

Edge to Edge |

Single Plane or Flat Part |

+/- 0.005" |

|

Edge to Hole |

Single Plane or Flat Part |

+/- 0.005" |

|

Hole to Hole |

Single Plane or Flat Part |

+/- 0.005" |

|

Hole to Diameter |

Single Plane or Flat Part |

+/- 0.005" |

|

Bend to Edge/Hole |

Single Plane or Flat Part |

+/- 0.010" |

|

Hole to Hole/Edge: Edge to Edge |

Multiple Planes, Bent Part |

+/- 0.030" |

|

Over Formed Part |

Multiple Planes, Bent Part |

+/- 0.030" |

|

Bend Angle |

Multiple Planes, Bent Part |

+/- 1 deg. |

Common Sheet Metal Finishes

Applications of Sheet Metal

-

Sheet Metal Part

-

Sheet Metal Parts

-

Sheet Metal Service

What are the advantages for sheet metal fabrication?

|

Advantages for Sheet Metal Fabrication |

|

|

Efficiency and Accuracy |

Through the use of the latest CAD/CAM and CNC technology and manufacturing equipment our sheet metal fabrication process is guaranteed to be efficient as well as accurate |

|

Durability and Malleability |

Sheet metals are strong enough to withstand high pressures, yet they are malleable. They can be formed into almost any shape, which means they are an ideal material for innovative architects and designers to work |

|

Diversity Material |

Sheet metal is of a low weight and thin gauge making transport and delivery of the product straightforward and cost effective. |

|

Easily Repairable |

Repairs can be carried out in a simple and straightforward way by removing an individual metal sheet from a structure and replacing it without having to dismantle an entire construction. |

|

Low Cost |

For all the reasons above – efficiency, durability, ease of transport and design – sheet metal fabrication offers customers a high quality yet inexpensive route to obtaining a product they can work with. |

Ready to Get a Sheet Metal Fabrication Quote?

The geometric structures, tight tolerance, and sheet metal materials including aluminum, steel, stainless steel, and copper, along with assembly services such as welding, installing PEM inserts, and secondary processing options, all of those are available as long as you work with our sheet metal fabricating. Under the prerequisite of guaranteed quality, we move forward to offer our customers the most competitive and cost-saving sheet metal fabricating plan and prices no matter for small-scale prototypes or large-scale production runs.