China Highest Level Military Parts Cnc Milling Manufacturers, Suppliers, Factory

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Highest Level Military Parts Cnc Milling,Highest Level Military Products Cnc Machining,Highest Level Military Components Cnc Machining, We attend seriously to produce and behave with integrity, and with the favor of consumers at your house and abroad during the xxx industry.

Highest Level Military Parts Cnc Milling, With the support of our highly experienced professionals, we manufacture and supply best quality items. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the require of customers to meet the requirement of customers.

Hot Products

Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

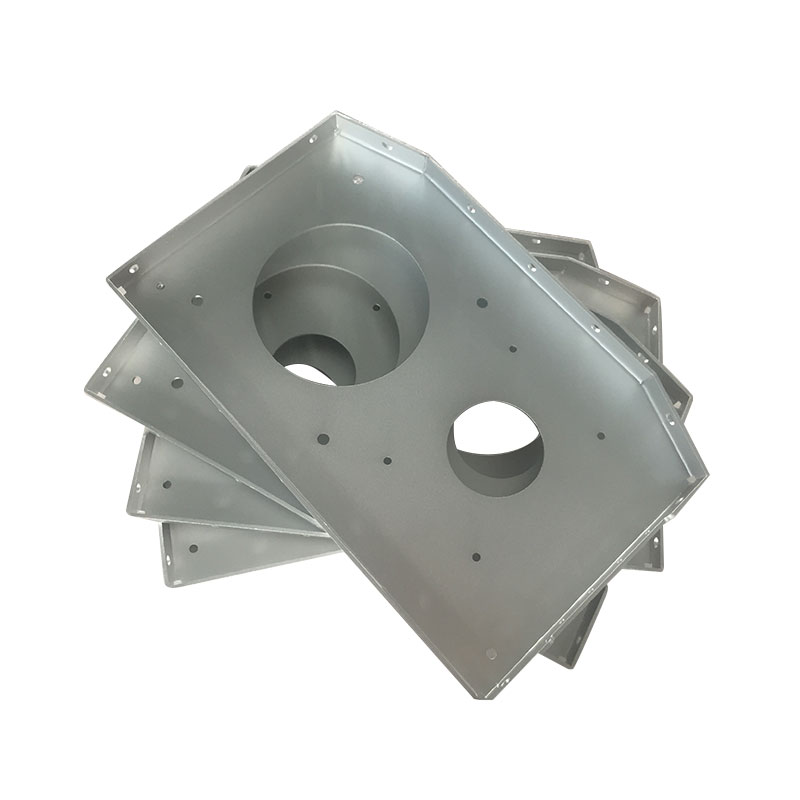

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts

Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts:If you need aluminum parts cnc machined we are one of the most capable and affordable sources specializing in manufacturing precision machined parts on advanced cnc machines. With rich knowledge and experience, our cnc machine shop is able to produce parts that require innovative tooling and fixturing in a timely manner with competitive price. We do cnc machining on 4,5 axis all kinds of aluminum with 6061 and 7075 being the most used.Plastic Electronic Products CNC Machining

The role of Plastic Electronic Products in the electronics industry has increased exponentially. The continual growth of electronic and engineering devices has led to the designing and manufacturing of various standard and custom plastic products, which can support industrial electronic applications.The following is about Plastic Electronic Products CNC Machining.Medical Device Fixture CNC Machining

The following is about Medical Device Fixture CNC Machining.Medical Device Liquid Silicone Vacuum Casting Parts

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about Medical Device Liquid Silicone Vacuum Casting Parts.Steel Aerospace Parts Rapid Prototype

Rapid prototype castings are fully functioning parts with the same strength and metallurgical properties as traditionally investment cast parts. However, they carry the added advantage of substituting injected wax patterns with 3-D printed patterns, resulting in a quick and relatively low-cost alternative for those who only need a limited number of parts.

Investment casting using rapid prototypes is a reliable means to quickly produce metal castings while in the preliminary design phases of an investment casting project. This allows you to test out a sample design, which can help avoid expensive tooling changes. Oftentimes, rapid prototype castings are less costly and time-consuming than the process of machining prototypes out of bar stock or producing prototypes through weldments.The following is about Steel Aerospace Parts Rapid Prototype.