Aerospace Parts Vacuum Casting

Shbury can make the silicon molds ready within days. It can make up to 50 copies of parts made from high-quality polymer. It’s a perfect low-cost manufacturing technique. We recommend vacuum casting to manufacture prototypes for proof of concept, visual aids for presentation, and design testing.

The parts made from vacuum casting are accurate, durable, and detailed. Shbury as aerospace parts vacuum casting factory in China can manufacture them using affordable polymers that need no further processing. That translates to cost savings because there are no finishing treatments needed on the finished parts.

Here are some applications of vacuum casting:

.Proof of concept

.Product testing

.Low volume manufacturing

Vacuum casting is used by a wide range of industries that includes energy, aerospace, manufacturing, electronics, engineering, and automotive.

- View as

Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.

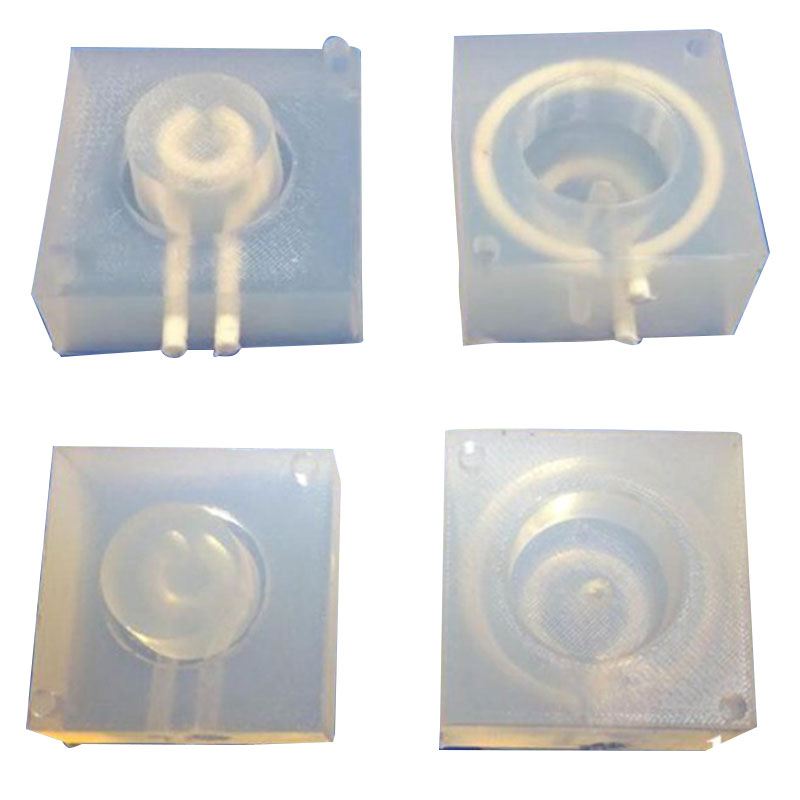

Read MoreSend InquiryAerospace Seal Parts Vacuum Casting

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands.The following is about Aerospace Seal Parts Vacuum Casting.

Read MoreSend InquiryAerospace Gasket Parts Vacuum Casting

Vacuum Casting may be used with a multitude of materials. This method of casting is typically made polyurethane prototype parts in a timely manner. A wide variety of textures, rigidity, strength, hardness or softness may be produced with this manufacturing technique. The parts are usually made with polyurethane resins because it can emulate the texture of other materials. The molds are typically made out of silicone and may even be produced with a 3D printer.The following is about Aerospace Gasket Parts Vacuum Casting.

Read MoreSend Inquiry