Rapid Prototype

Rapid Prototyping is the fast fabrication of a physical part, model or assembly using 3D computer aided design (CAD). The creation of the part, model or assembly is usually completed using additive manufacturing, or more commonly known as 3D printing.

As the fastest rapid prototyping factory, Shbury’s main aim is let our customers received the prototypes asap, our the fastest time is 72hours to finish rapid prototypes.

- View as

Medical Glucose Meter Device Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.

Read MoreSend InquiryMedical Infusion Pump Housing Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Infusion Pump Housing Rapid Prototypes.

Read MoreSend InquiryMedical X-ray Housing Rapid Prototypes

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.

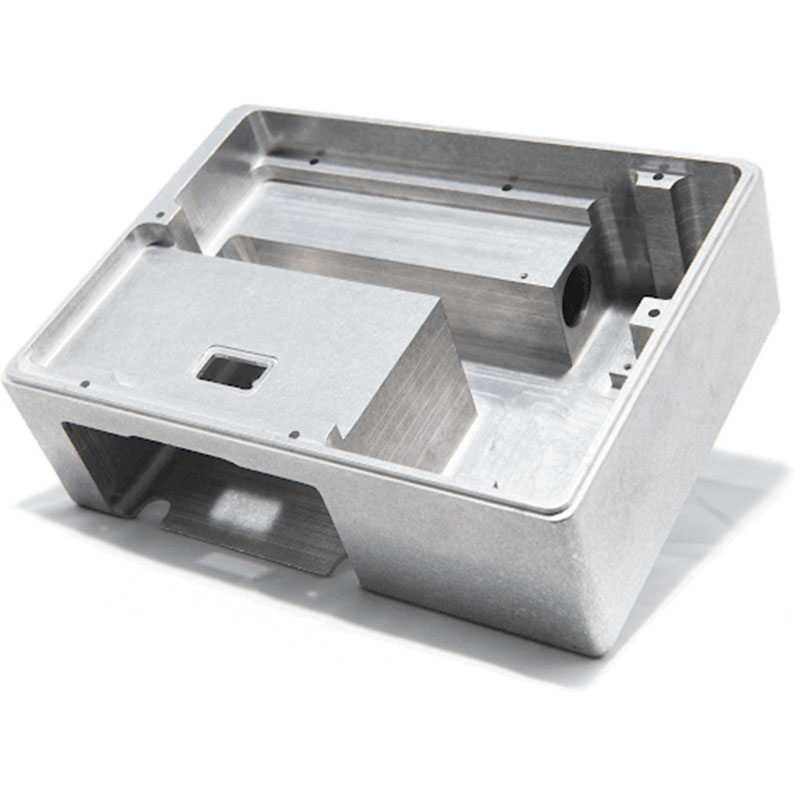

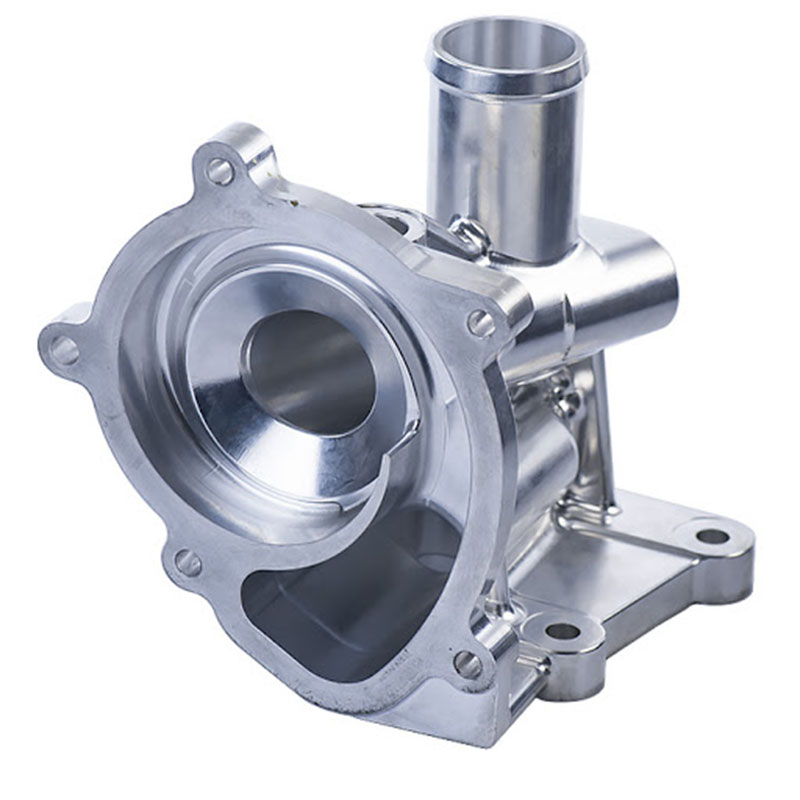

Read MoreSend InquiryAluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.

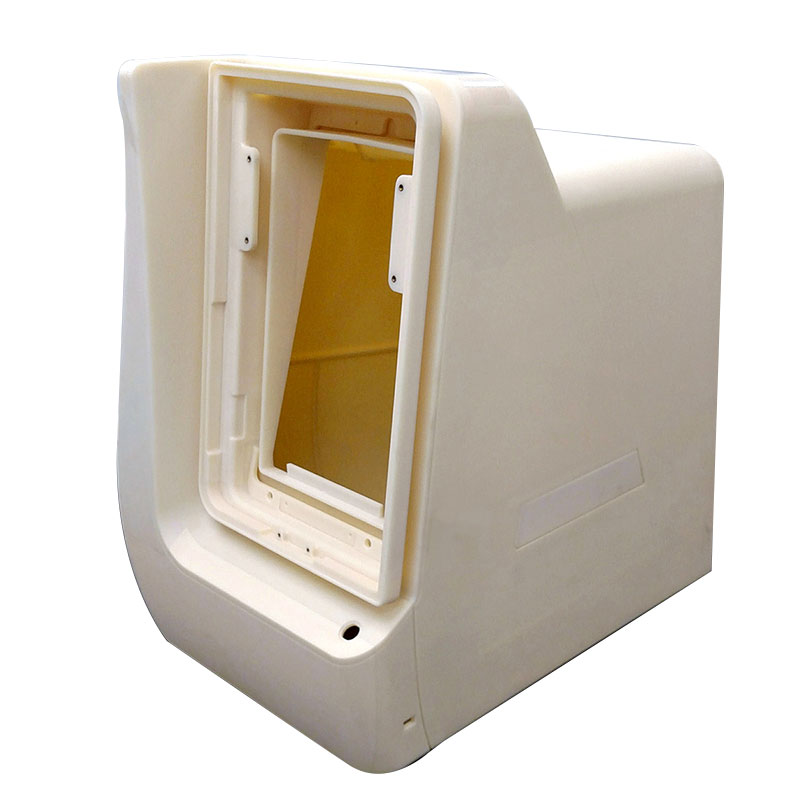

Plastic Electronic Products Rapid Prototypes

Do you require quick, economic plastic prototypes with production-like material properties? Vacuum casting in silicone molds is the method that you need. Due to the low die costs, vacuum casting is particularly attractive as an economical secondary procedure for the reproduction of models in small batches.The following is about Plastic Electronic Products Rapid Prototypes.

Read MoreSend Inquiry3D Printing Electronic Products Rapid Prototypes

Consumers have come to expect periodic releases of ever-more advanced electronics. From smartphones to smart home systems and wearables, new consumer products require significant evaluation and testing before they hit the market. Before moving to mass manufacturing, these new products require rigorous testing for quality, functionality, and user experience.

With new consumer product upgrade and release cycles becoming tighter, electronics designers need a solution that helps reduce the time involved in each R&D and prototyping cycle. By far, the most time-consuming and least productive portion of R&D is repetitive design, build, and test cycles.

Rapid prototyping with traditional manufacturing processes is anything but fast, so designers need a real solution for true rapid prototyping. This illustrates the value of 3D printing in consumer electronics development and prototyping; designers can quickly create fully-functional electronics in a matter of hours rather than days, and this can be done in-house. Designers can innovate more often, quickly test functionality, and implement redesigns before manufacturing at scale. The following is about 3D Printing Electronic Products Rapid Prototypes.