Aluminium Mechanical CNC Machining Parts Anodizing

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through. Anodizing is a process for finishing aluminum alloys that employs electrolytic oxidation of the aluminum surface to produce a protective oxide coating. The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Conventional coatings are 0.1 to 1.0 mil thick and are essentially transparent but they may be colored like sample above.The following is about Aluminium Mechanical CNC Machining Parts Anodizing.

Send Inquiry

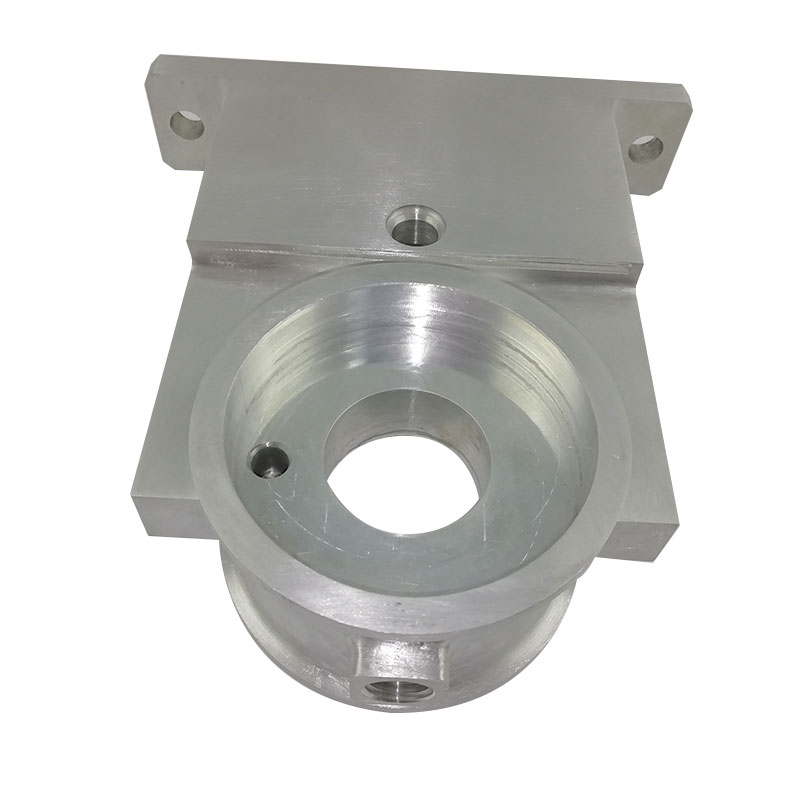

Aluminium Mechanical CNC Machining Parts Anodizing

To meet the customers' over-expected pleasure , we've our sturdy group to offer our best overall service which incorporates advertising and marketing, product sales, designing, production, good quality managing, packing, warehousing and logistics for Reasonable price China Supplier MAluminium Mechanical CNC Machining Parts Anodizing, As an expert specialized with this field, we have been committed to solving any problem of significant temperature protection for users. Reasonable price China Spare Parts, Motorcycle Parts, We have been sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

1.Aluminium Mechanical CNC Machining Parts Anodizing Services

It's a CNC mill work for aluminium anodizing parts. After cnc machining is complete the part is anodized blue.

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through. Anodizing is a process for finishing aluminum alloys that employs electrolytic oxidation of the aluminum surface to produce a protective oxide coating. The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Conventional coatings are 0.1 to 1.0 mil thick and are essentially transparent but they may be colored like sample above.

2.Product Parameter for Aluminium Mechanical CNC Machining Parts Anodizing

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNCmachining |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

Surface finish

|

Aluminum parts |

|

|

Clear Anodized |

Chemical Film |

|

Color Anodized |

Brushing |

|

Sandblast Anodized |

Polishing |

3.Product Feature for Aluminium Mechanical CNC Machining Parts Anodizing

|

Material |

Aluminium 6061-T6 |

|

Machines type |

cnc machines |

|

Surface finishing |

orange anodizing |

|

dimensions |

132*125*45mm |

|

Special type |

Hole, thread |

|

capacity |

600pcs per month |

4.Product Details for Aluminium Mechanical CNC Machining Parts Anodizing

Why Anodize Precision Machined Components?

Anodizing precision machined components provides a reliable and relatively inexpensive means of improving the wear resistance, and coloring aluminum and other nonferrous metals. First developed in the 1920s, this electrochemical process revolutionized numerous industries with a need for lightweight, strong, corrosion-resistant aluminum extrusions for window frames, decorative exterior panels and many other architectural elements.

Today it protects satellites, skyscraper facades and components for a wide variety of industries from aerospace to medical and is one of the most efficient ways to make aluminum parts that last and require little maintenance.

5.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail , we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

6.Deliver,Shipping for Aluminium Mechanical CNC Machining Parts Anodizing