Auto Track Hubs Frame Parts CNC Machining

Send Inquiry

Auto Track Hubs Frame Parts CNC Machining

We persist with our business spirit of "Quality, Effectiveness, Innovation and Integrity". We aim to create a lot more value for our consumers with our wealthy resources, sophisticated machinery, experienced workers and outstanding providers for 2019 wholesale price China Custom Aluminum Precision Auto Track Hubs Frame Parts CNC Machining, We encourage you to make get hold of as we've been seeking for associates inside our venture. We are sure you are going to locate doing business enterprise with us not only fruitful but also profitable. We are all set to provide you with what you require. 2019 wholesale price China OEM CNC Machining Used Auto Parts, Customized Auto Parts CNC Machining Spare, Why we can do these? Because: A, We have been honest and reliable. Our solutions have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will probably be highly appreciated.

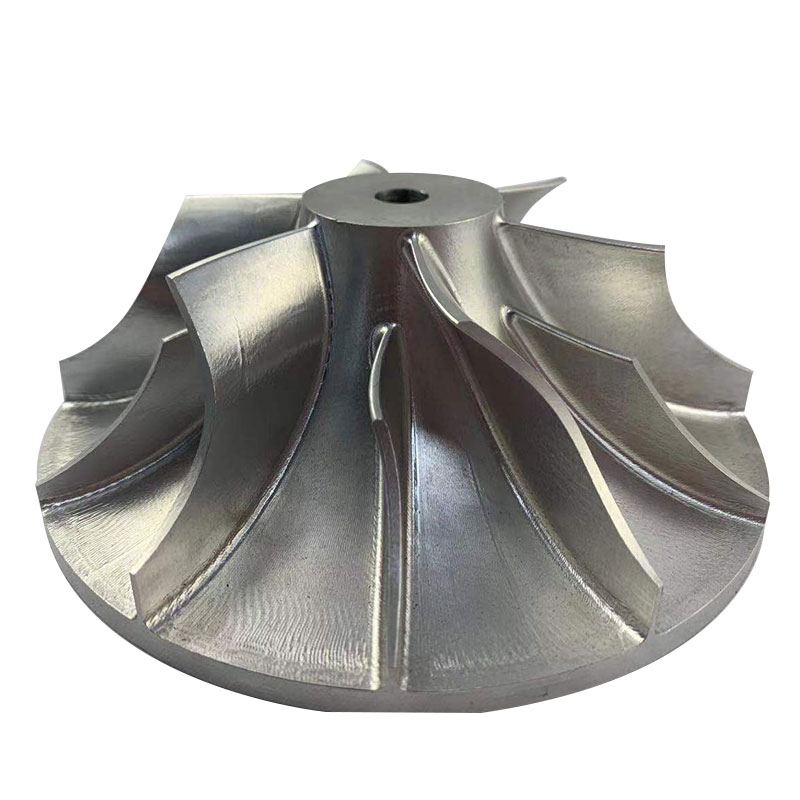

1.Auto Track Hubs Frame Parts CNC Machining Services

Simple to complex part turning and milling machining services for Automotive industries.

For automotive parts and parts machining,Shbury offers the highest degree of OEM service with a basis of 10+ years experience serving the automotive industry. Our automotive precision shop and experts deliver confidence. We have perfected the art of producing large component volumes with complete Shbury reliability, backed by the quality and long-term reliability our customers expect.

2.Product Parameter for Auto Track Hubs Frame Parts CNC Machining

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNCmachining |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

|

Clear Anodized |

Polishing |

Zinc plating |

|

Color Anodized |

Passivating |

Oxide black |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

|

Chemical Film |

Laser engraving |

Chrome plating |

|

Brushing |

|

Carburized |

|

Polishing |

|

Hot treatment |

|

Chroming |

|

Powder Coated |

3.Product Feature for Auto Track Hubs Frame Parts CNC Machining

★ Brake System Components: Titanium Valve Keepers

★ Small Auto Parts: Dowel Pins,Splined Shafts,Bushings

★ Pretotype Auto Parts: Timing Covers,Valve Retainers

★ Vibration Control Series:Powertrain-Mounting, Rubber Metal Parts,Torsional Vibrational Damper Parts etc

★ Power Chassis System: Steering Knuckle, Control Arm,Bearing-sleeve, Car Support etc

★ Light Alloy Structural Parts: Chassis Bracket,Shock Tower,Longitudinal Beam,B-Pillar

★ Other Parts: Non-Standard Wheel hub,Car model prototype parts,Wheel hub shaft

4.Product Details for Auto Track Hubs Frame Parts CNC Machining

Why Use CNC Machining ForAuto track hubs frame parts?

The benefits of CNC machining are numerous. Once a tool path is created and a machine is programmed, it can run a part 1 time, or 100,000 times. CNC machines are built for precise manufacturing and repeatability which makes them cost-efficient and highly scalable. CNC machines can also work with a variety of materials from basic aluminum and plastics to more exotic materials like titanium — making them the ideal machine for almost any job. That's why CNC machining is one of the most popular methods of making plastic and metal components.

5.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail , we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A6:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A8:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

7.Deliver,Shipping for Auto Track Hubs Frame Parts CNC Machining