Indirectly Human Medical Device Parts CNC Machining

Send Inquiry

Indirectly Human Medical Device Parts CNC Machining

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for High Quality for China Precise Indirectly Human Medical Device Parts CNC Machining, We sincerely welcome all guests to setup small business associations with us on the basis of mutual positive aspects. You should get in touch with us now. You'll get our professional reply within 8 hours. High Quality for China CNC Milling Parts, CNC Machining Medical Parts, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

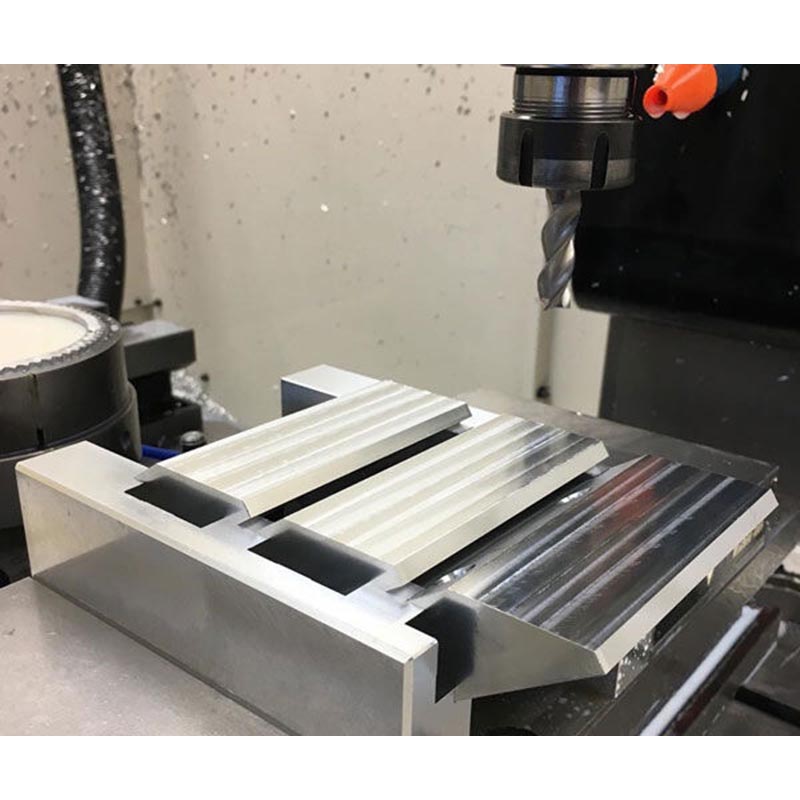

1.Indirectly Human Medical Device Parts CNC MachiningServices

Many machined medical parts are made by specialist medical machine shops. These shops must be capable of making parts with extremely tight tolerances and may have a focus on bio-safe and biocompatible materials. Crucially, they must also be capable of making parts that meet international and governmental standards, such as those set by the American Food and Drug Administration (FDA).

That being said, any machine shop capable of precision machining has the technical resources to make medical parts. Items like bodily implants require exceptionally tight tolerances and therefore require precision machining, but medical-grade materials are available to all machine shops.

2.Product Parameter forIndirectly Human Medical Device Parts CNC Machining

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNC machining |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316L, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

|

Clear Anodized |

Polishing |

Zinc plating |

|

Color Anodized |

Passivating |

Oxide black |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

|

Chemical Film |

Laser engraving |

Chrome plating |

|

Brushing |

|

Carburized |

|

Polishing |

|

Hot treatment |

|

Chroming |

|

Powder Coated |

3.Product Feature forIndirectly Human Medical Device Parts CNC Machining

Basic requirements forIndirectly Human Medical Device Parts CNC Machining include:

· Precision machining to tight tolerances (as tight as 0.0001” inches for some parts)

· 4-axis and 5-axis machining for complex geometries

· Ultra-high level of cleanliness, especially for an implant manufacturer

· A wide material selection that includes stainless steel and medical-grade plastics such as PEEK

· High-level surface finishing capabilities

4.Product Details for Indirectly Human Medical Device Parts CNC Machining

Surgical instruments are simple devices often consisting of one or two metal parts. But CNC machines can be used to create parts for much more complex pieces of equipment. Think heart rate monitors, MRI scanners and X-ray machines.

These expensive pieces of equipment may comprise hundreds or thousands of individual parts, and many of these parts can be fabricated with CNC machines.

Machined equipment parts can include small components like switches, buttons and levers, and larger items such as to monitor housings.

All of these components must be high standards in order to eliminate any chance of machine failure, especially since medical equipment is regularly wheeled from room to room around a hospital.

However, unlike implants and surgical tools, these parts may not need to be biocompatible or bio-safe, since they may never make direct contact with a patient. As such, a much wider variety of CNC machining materials can be used.

Electronic medical equipment commonly fitted with machined parts

Ultrasound equipment

MRI scanners

CT scanners

Diagnostic equipment

Monitors

Lighting

5.Product Application forIndirectly Human Medical Device Parts CNC Machining.

CNC Machining are widely used, and almost all products that

can use metal parts can be used. Such as aerospace products, auto parts,

electronic products, mechanical equipment parts, medical equipment, defense and

military supplies.

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

7.Deliver,Shipping forIndirectly Human Medical Device Parts CNC Machining.