Plastic Electronic Products Rapid Prototypes

Send Inquiry

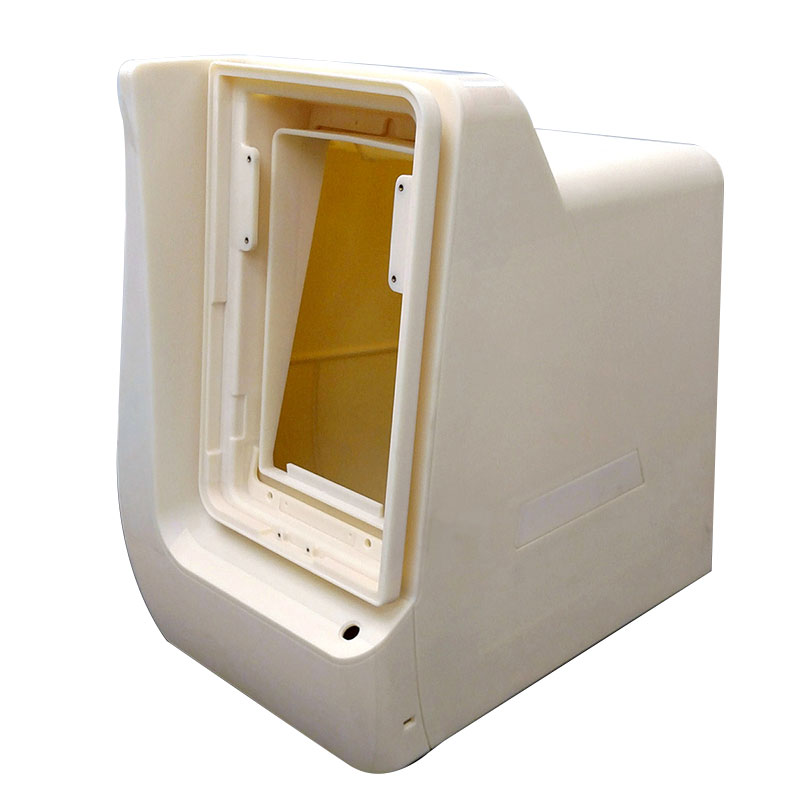

Plastic Electronic Products Rapid Prototypes

Do you require quick, economic plastic prototypes with production-like material properties? Vacuum casting in silicone molds is the method that you need. Due to the low die costs, vacuum casting is particularly attractive as an economical secondary procedure for the reproduction of models in small batches.

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We've been striving to be an excellent business enterprise partner of you for OEM/ODM Factory China Professional OEM Machining Parts Plastic Electronic Products Rapid Prototypes, In case you have the requirement for almost any of our products and solutions, you should contact us now. We have been looking forward to hearing from you soon. OEM/ODM Factory China Injection Mold Plastic Mould, Plastic Manufacturer Moulded, With nearly 30 years' experience in business, we have been confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

1.Product ParameterforPlastic Electronic Products Rapid Prototypes

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNC machining |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

CNC Plastic |

ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

|

Vacuum casting plastic |

ABS, PC,PA,PP,PE, PMMA etc |

|

3D printing plastic |

ABS, PC,PA,PP,PE,etc |

Surface finish

|

Plastic |

|

|

Plating |

polishing |

|

Painting |

Laser engraving |

2.Product Feature for Plastic Electronic Products Rapid Prototypes

|

Materials |

ABS, PC |

|

Surface finishing |

Painting, polishing |

|

Application |

Electronic housing |

|

MOQ |

1PCS |

|

Lead time |

7days |

3.Product Details forPlastic Electronic Products Rapid Prototypes

When to use rapid prototyping: a case study

Rapid prototyping is ideal for plastic parts that need to be a precise size or fit. To achieve precision, engineers and product developers will often need to test the plastic prototype multiple times within a short period to meet deadlines. Rapid prototyping, as the name suggests, offers this advantage.

A protector cap, like those used for bolt heads, is a good example of a product that benefits from rapid prototyping because it must be an exact fit. Because the fitting must be precise, the mold needs to be equally precise.

Once you finish the rapid prototyping phase, it’s an easy next step to move on to production with injection molding.

4.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

6.Deliver,Shipping for Plastic Electronic Products Rapid Prototypes