China 4 axis Aluminium Anodizing Parts Manufacturers, Suppliers, Factory

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for 4 axis Aluminium Anodizing Parts,Aluminum 4 axis CNC Machining,CNC Machining, We invites both you and your enterprise to thrive along with us and share a vibrant long term in global sector.

4 axis Aluminium Anodizing Parts, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We're looking for the wholesale, Drop ship. Remember to contact us if you are interesting our goods. Hope to do business with you all. High quality and fast shipment!

Hot Products

Medical Glucose Meter Device Rapid Prototypes

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.The following is about Medical Glucose Meter Device Rapid Prototypes.Aircraft Seat Frame Parts Rapid Prototypes

Innovative prototypes from aerospace engineering workshops are already in flight today. Rapid prototyping is already being used to produce specific aircraft interior components such as air ducts, armrests, seat frames end caps, seat framework and wall panels. Prototyping will be an integral piece of the manufacturing and new part development processes for years to come. The prototypes from aerospace engineering will without a doubt be at the center of space exploration as well as the coming transportation revolution.The following is about Aircraft Seat Frame Parts Rapid Prototypes.Low Volume Production Military Parts Vacuum Casting

Vacuum casting is a low-cost but reliable method for making a small number of high-quality prototypes based on a master model. This method is ideal for rapid prototyping used in engineering testing, proof-of-concept and display demos. On superior prototype, we have a dedicated team of mold makers who are experts at creating vacuum casting molds for many years.The following is about Low Volume Production Military Parts Vacuum Casting.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.Tight Tolerance Military Parts CNC Machining

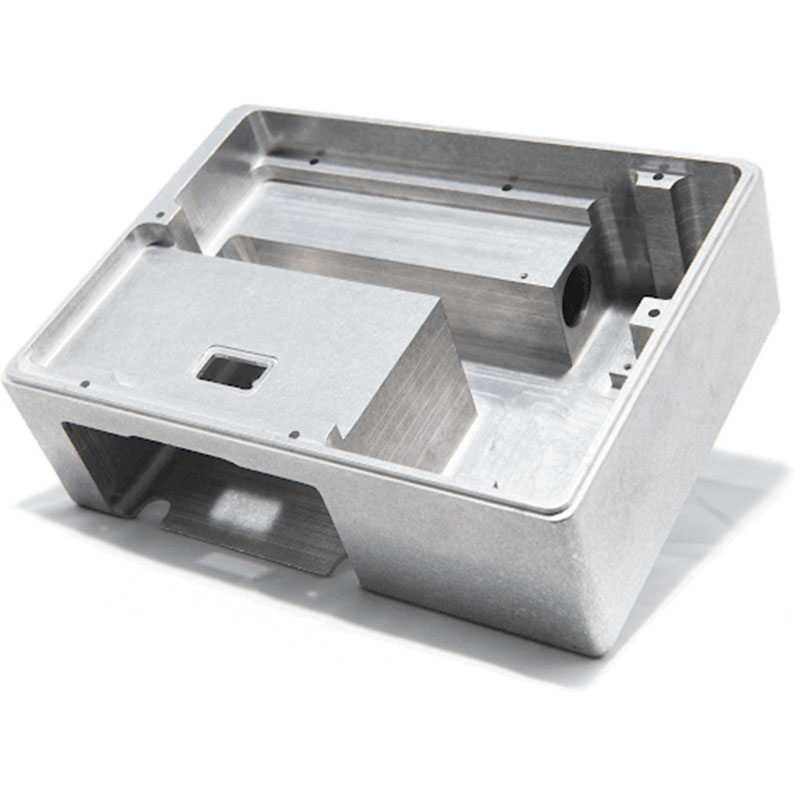

Tight Tolerance Military Parts CNC Machining with more than 10 years in the rapid manufacturing business, Shbury has built up rich experience in CNC machining parts for both prototyping and mass production. we can achieve tight tolerances on CNC machined parts.Medical Device Fixture CNC Machining

The following is about Medical Device Fixture CNC Machining.