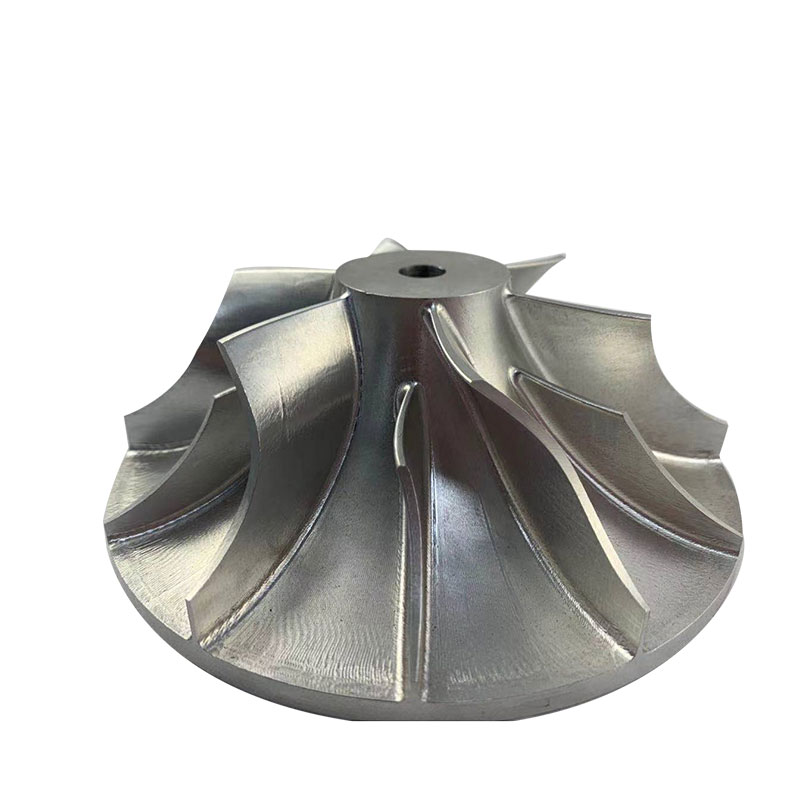

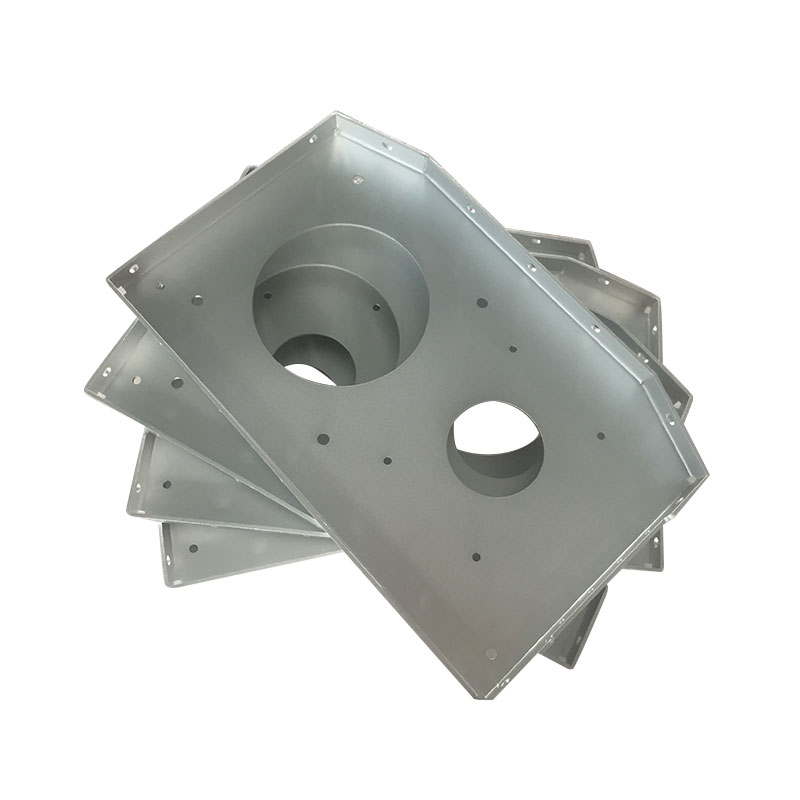

CNC Machining 4 axis Aluminium Anodizing Parts

Send Inquiry

CNC Machining 4 axis Aluminium Anodizing Parts

we are specialized manufacturers from China, Aluminum Block, Cnc Milling Machining Parts suppliers/factory, wholesale high-quality products of Aluminum Cnc Machining Parts R & D and manufacturing, we have the perfect after-sales service and technical support. Look forward to your cooperation!

1.Product Parameter for CNC Machining 4 axis Aluminium Anodizing Parts

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNC Machining |

510 * 1020 * 500 mm(max) |

+/-0.02 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

|

Plastic |

ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

|

titanium |

TC4 ,GR5 , Ti6AL4V |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

Plastic |

|

Clear Anodized |

Polishing |

Zinc plating |

Plating |

|

Color Anodized |

Passivating |

Oxide black |

Painting |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

polishing |

|

Chemical Film |

Laser engraving |

Chrome plating |

Laser engraving |

|

Brushing |

|

Carburized |

|

|

Polishing |

|

Hot treatment |

|

|

Chroming |

|

Powder Coated |

|

Aluminum 4 axis CNC Machining Services Offered

Material Grades We Work With

2,Product Feature for CNC Machining 4 axis Aluminium Anodizing Parts

|

Software |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Material |

aluminium |

|

Surface |

Red anodizing |

|

Lead time |

200pcs for 7days |

|

Application |

plate parts |

|

MOQ |

1piece |

|

Machine type |

4 axis |

3,Product Details for CNC Machining 4 axis Aluminium Anodizing Parts

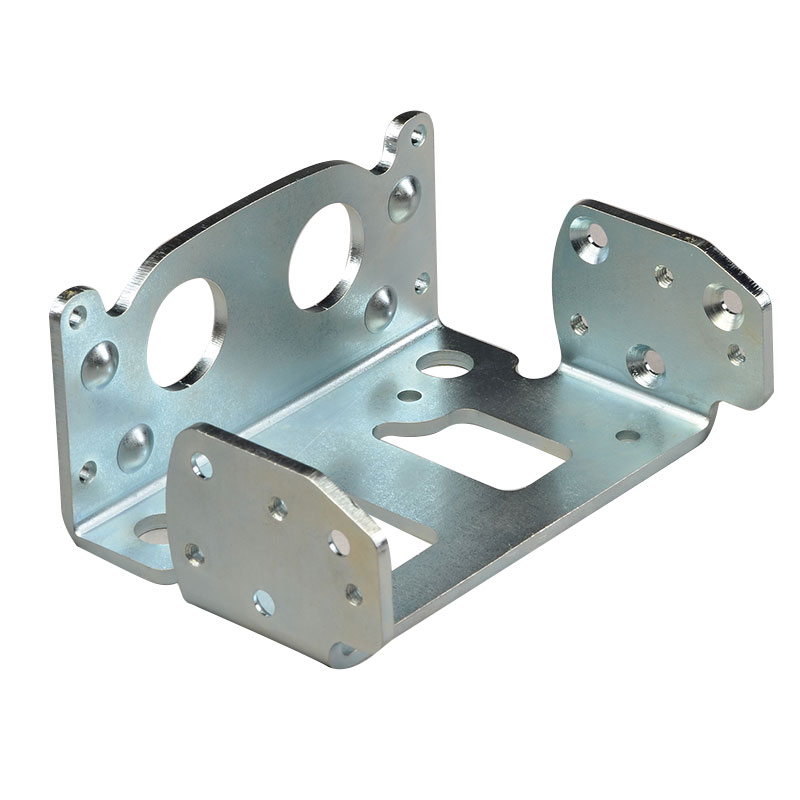

At Shbury, we manufacture various aluminum parts through the following processes:

• Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts.

• CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub operations, such as knurling, milling, drilling, etc.

• Production Wire EDM: At Shbury, we produce high precision machine parts using 4 axis wire EDM. Additionally, we have the capability of providing tapered cuts up to 45 degrees.

At Shbury , we work with the following aluminum grades:

• Aluminum 6061: This grade is one of the most popular aluminum grades, due to its excellent mechanical properties, as well as weldability. Aluminum 6061 is most commonly extruded grade, due to its typical properties, such as good toughness, medium to high strength, excellent corrosion resistance in harsh environments, easy anodization, and good workability. Aluminum 6061 is extensively used for 5 axis CNC machining.

• Aluminum 7075: This is a popular grade after 6061. Aluminum 7075 is well-known for its excellent fatigue strength. This grade is not easily weldable and is one of the extremely expensive variants available. Hence, it is most commonly used for tough components, such as aircraft wings, and fuselages, bicycle components, rock climbing equipment. This alloy has better corrosion resistance than the aluminum 2000 alloys. Most times, machine operations are conducted using oil lubricants.

• Aluminum 2024: The alloy is widely used in aerospace and military applications, due to its mechanical properties, such as high fatigue resistance, high strength, and susceptibility to thermal shocks. Aluminum 2024 is not easily weldable and offers poor corrosion resistance, too.

• Aluminum 5052: This non-heat treatable alloy is regularly used for building machine parts, and components to be used in salt water environments. Aluminum 5052 offers good resistance to marine, saltwater, and industrial environments. The alloy can be easily punched, bent, and sheared into desired shapes.

• Aluminum 6063: The alloy has excellent mechanical properties, such as easy weldability, heat treatability, and durability. Aluminum 6063 is used for aluminum extrusion applications. This alloy is commonly used for creating complex shapes with smooth surfaces and is commonly used in applications such as door frames, window frames, sign frames, roofs, etc.

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A6:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A8:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

5.Deliver,Shipping for Eco-friendly Low Price CNC Machining Aluminum anodizing Plate Parts