China Eco-friendly CNC Machining Aluminum anodizing Plate Parts Manufacturers, Suppliers, Factory

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Eco-friendly CNC Machining Aluminum anodizing Plate Parts,CNC Machining Aluminum anodizing Plate Parts, We've been willing to provide you with the lowest selling price during the market place, greatest high quality and quite nice sales service.Welcome to do bussines with us,let's be double win.

Eco-friendly CNC Machining Aluminum anodizing Plate Parts, We are going to supply much better items with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

Hot Products

Stainless Steel Passivating Mechanical Rapid Prototypes

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, water, and chemically etched media such as acid, alkali, salt, etc., also known as stainless acid-resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter generally has rust.The following is about Stainless Steel Passivating Mechanical Rapid Prototypes.Electronic Hookah Nozzle Products CNC Turning

The following is about Electronic Hookah Nozzle Products CNC Turning.PEEK Auto Parts Rapid Prototyping

The following is about PEEK Auto Parts Rapid Prototyping.Metal Aerospace Parts CNC Machining

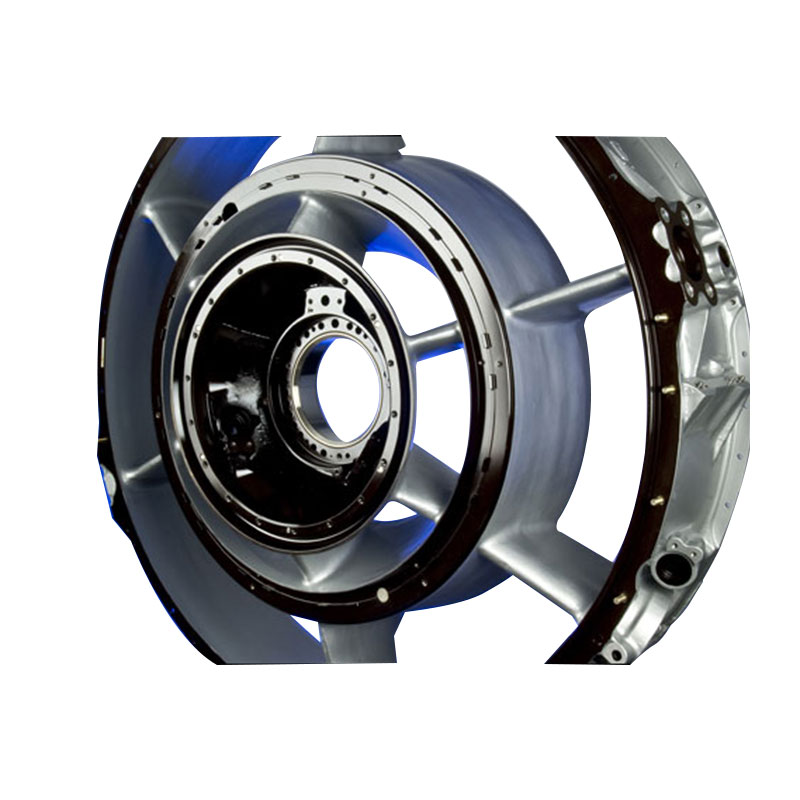

A leader in manufacturing complex details and components for the aerospace industry, shbury provides metal aerospace parts CNC machining. Several in-house processes, including precision CNC turning, CNC milling, lapping and OD grinding are incorporated to fabricate the cnc parts. We also perform in-house deburring and dot peen marking. Outside services sourced to our vendor base include heat treatment and a tungsten carbide plasma spray coating. Tolerance requirements are held to +-0.01mm, a circular run out of +-0.005mm. , Dimensional inspection as well as NDT inspection was done in-house.Laser Cutting Auto Parts Rapid Prototypes

Shbury offers rapid prototyping services for laser cut parts. Laser technology allows us to manufacture parts quickly and cost-effectively, allowing us to provide your team with a precision part prototype quickly and cost-effectively. Using the latest CNC technology, we can use your CAD drawings to produce a part without the delays required to design and manufacture tooling.The following is about Laser Cutting Auto Parts Rapid Prototypes.Aerospace Seal Parts Vacuum Casting

Silicone is cheaper in terms of cost compared to the injection mold. The reason for this difference in cost, is the nature of injection mold, being built on steel or aluminum parts. The cost if silicone mold can be from hundreds to thousands while the injection one will range from thousands to tens of thousands.The following is about Aerospace Seal Parts Vacuum Casting.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy