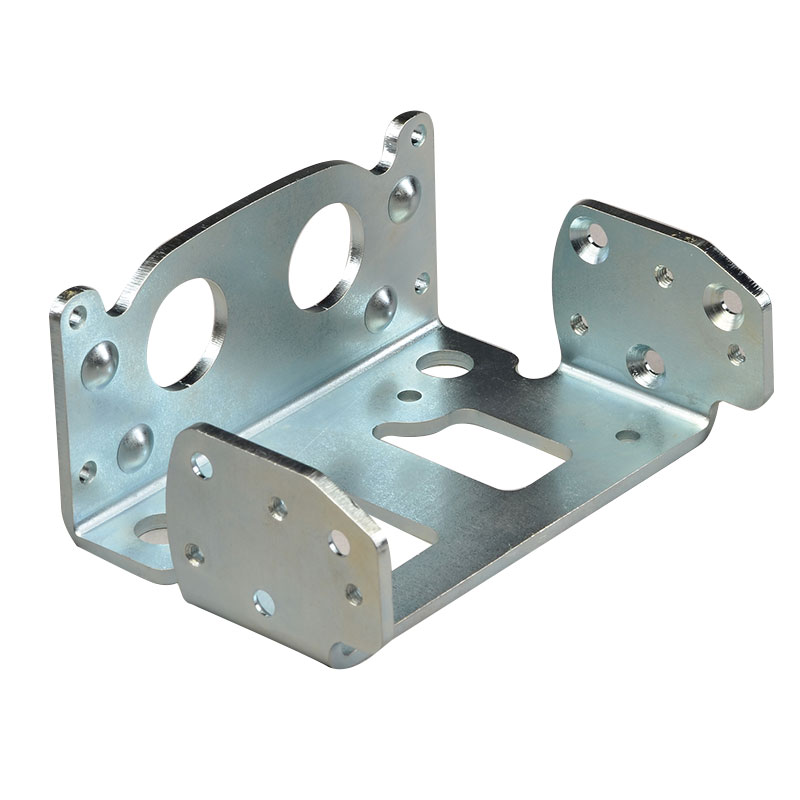

China Galvanized Sheet Bending Parts Manufacturers, Suppliers, Factory

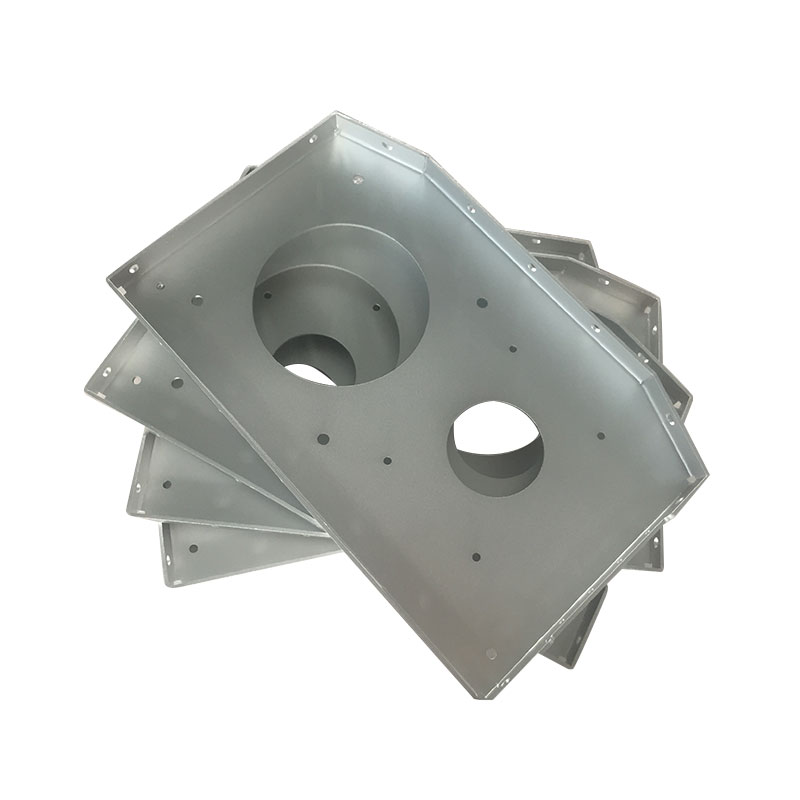

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Galvanized Sheet Bending Parts,Galvanized Metal Bending Parts and Galvanized Sheet Metal,Metal Sheet Forming Steel Bending Parts Bending Steel Plate,Galvanized Sheet Bending Equipment Metal Parts Sheet Metal,CNC Bending Galvanized Sheet Metal Fabrication Parts, In a word, when you choose us, you choose a ideal existence. Welcome to visit our factory and welcome your get! For even further inquiries, remember to usually do not hesitate to make contact with us.

Galvanized Sheet Bending Parts, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Hot Products

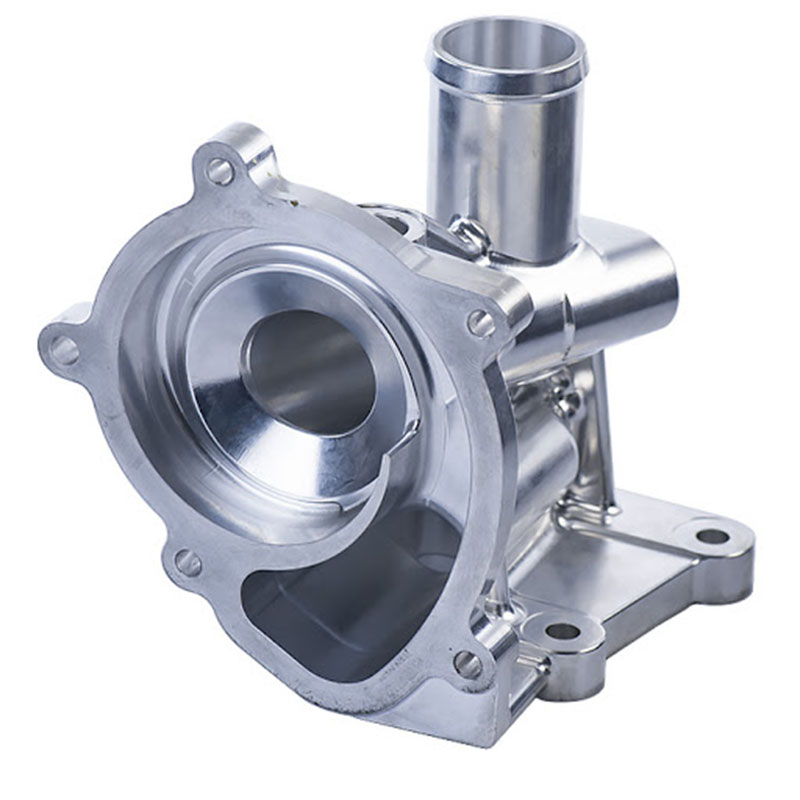

Auto Hydraulic Valve Parts CNC Machining

For more than 10years,Shbury Tech has specialized in machining and manufacturing a wide range of hydraulic parts and components. Our state-of-the-art CNC machining capabilities allow us to provide hydraulic machining services for many industries.

Our qualified engineering team and skilled CNC machinists use advanced machining equipment to produce complex fluid control hydraulic parts at high levels of quality and precision.

We manufacture a variety of individual hydraulic components and parts such as cylinder & rods, components for motors, pumps, fittings and hose hardware. Our range of secondary services, including anodizing, heat treating, passivating, plating, and assembly, gives us the ability to provide single-source solutions that simplify our customer’s supply chain, thus reducing manufacturing costs and improving turnaround times and overall customer satisfaction. The following is about auto hydraulic valve parts CNC machining.Aluminum Sheet Metal Bending Stamping Fabrication

High quality Aluminum Sheet Metal Bending Stamping Fabrication made in China. Guoye Optoelectronics is Aluminum Sheet Metal Bending Stamping Fabrication manufacturer and supplier in China.Metal Aerospace Parts CNC Machining

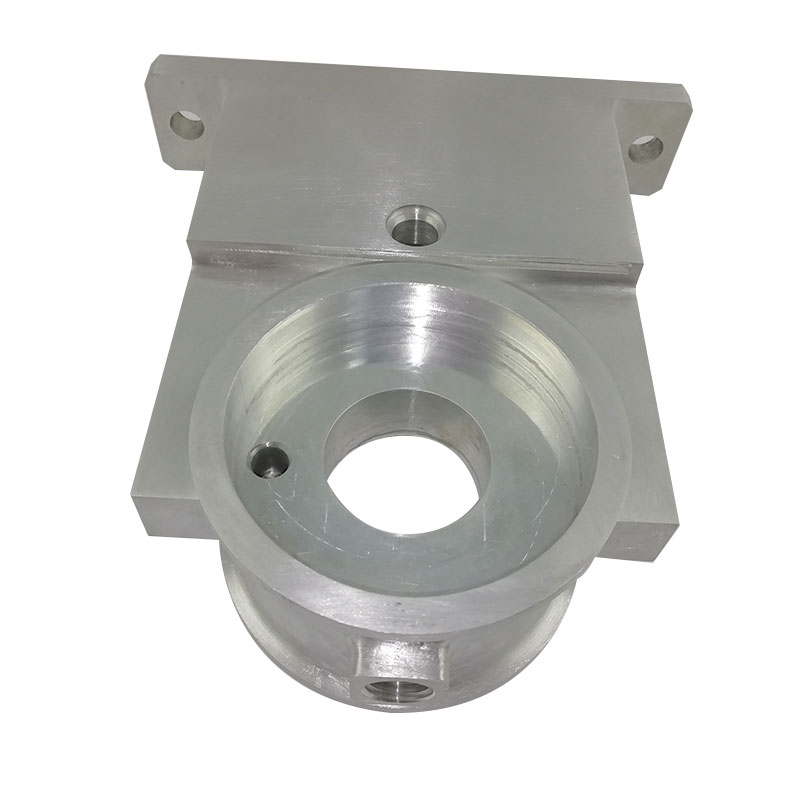

A leader in manufacturing complex details and components for the aerospace industry, shbury provides metal aerospace parts CNC machining. Several in-house processes, including precision CNC turning, CNC milling, lapping and OD grinding are incorporated to fabricate the cnc parts. We also perform in-house deburring and dot peen marking. Outside services sourced to our vendor base include heat treatment and a tungsten carbide plasma spray coating. Tolerance requirements are held to +-0.01mm, a circular run out of +-0.005mm. , Dimensional inspection as well as NDT inspection was done in-house.Agricultural Machinery Parts CNC Machining

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.High Precision Medical Device Parts CNC Machining

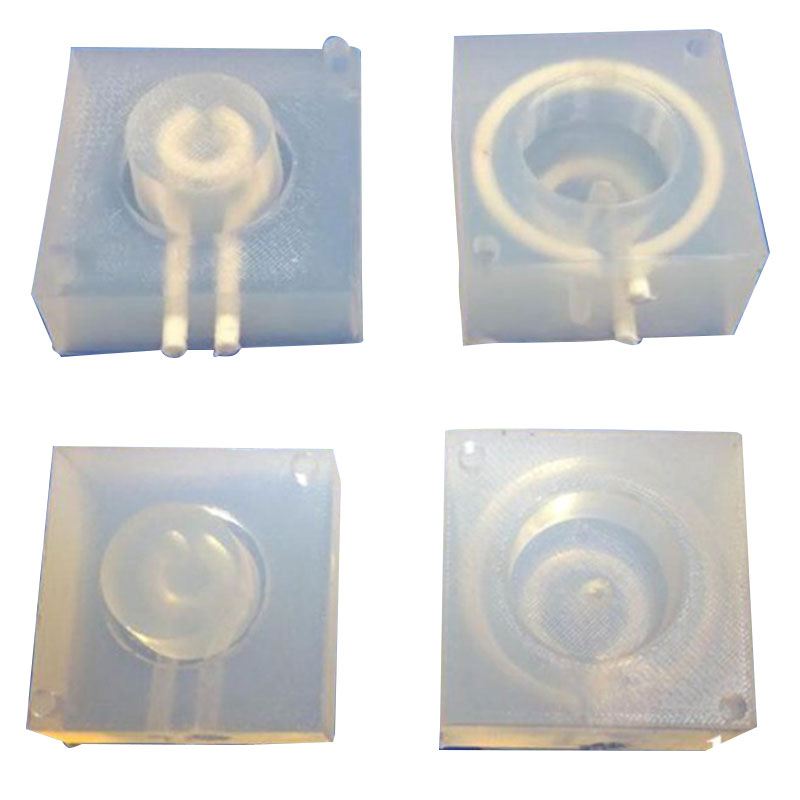

High Precision Medical Device Parts CNC Machining Shbury is a trusted supplier of medical device parts. Shbury is committed to improving the quality of life for patients and medical staff throughout the industry. Backed by over 10 years of CNC experience, our skilled machinists are able to create a custom medical component with the greatest accuracy possibleSheet Metal Stamping Precision Stamping Parts

Hot sale quality Sheet Metal Stamping Precision Stamping Parts with Low Price made in China. Guoye Optoelectronics is Sheet Metal Stamping Precision Stamping Parts manufacturer and supplier in China.