China Metal Sheet Forming Steel Bending Parts Bending Steel Plate Manufacturers, Suppliers, Factory

We purpose to understand quality disfigurement in the creation and provide the ideal services to domestic and abroad shoppers wholeheartedly for Metal Sheet Forming Steel Bending Parts Bending Steel Plate,Galvanized Sheet Bending Parts,Galvanized Metal Bending Parts and Galvanized Sheet Metal,Galvanized Sheet Bending Equipment Metal Parts Sheet Metal,CNC Bending Galvanized Sheet Metal Fabrication Parts, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

Metal Sheet Forming Steel Bending Parts Bending Steel Plate, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Hot Products

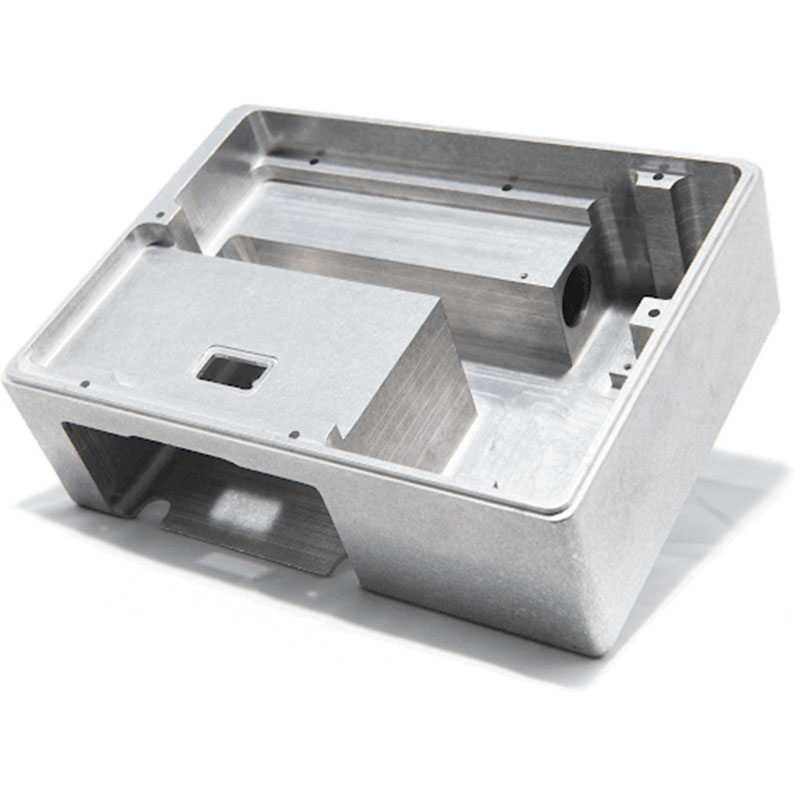

OEM Precision CNC Machining aluminium Anodizing Spare Parts

OEM Precision CNC Machining aluminium Anodizing Spare Parts:Before we look into aluminum parts anodizing, we should understand the exact meaning and purpose of anodizing. Generally, anodizing is a process through which a layer of metal oxide is electrolytically embedded onto the surface of the pure metal, in this case, Aluminum pars anodizing is like painting but when anodizing, the oxide layer is fully integrated into the underlying metal. Because of this, it can hardly chip or peel. Anodizing is the result of a highly controlled oxidation process that converts the surface of the metal into a corrosion-resistant, durable cover.Auto Track Hubs Frame Parts CNC Machining

Simple to complex part turning and milling machining services for Automotive industries. For automotive parts and parts machining,Shbury offers the highest degree of OEM service with a basis of 10+ years experience serving the automotive industry. Our automotive precision shop and experts deliver confidence. We have perfected the art of producing large component volumes with complete Shbury reliability, backed by the quality and long-term reliability our customers expect.The following is about auto track hubs frame parts CNC machining.High Demand Aerospace Parts CNC Machining

Aluminum alloy high demand aerospace parts CNC Machining has a widely application in many industries, as Aluminum is one of the most commonly used metals which is durable, lightweight, malleable, low cost, and recyclability.Aluminium Mechanical CNC Machining Parts Anodizing

It's a CNC mill work for aluminium anodizing parts. After cnc machining is complete the part is anodized blue.

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through. Anodizing is a process for finishing aluminum alloys that employs electrolytic oxidation of the aluminum surface to produce a protective oxide coating. The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Conventional coatings are 0.1 to 1.0 mil thick and are essentially transparent but they may be colored like sample above.The following is about Aluminium Mechanical CNC Machining Parts Anodizing.Polishing Cast Bronze Brass Copper Casting

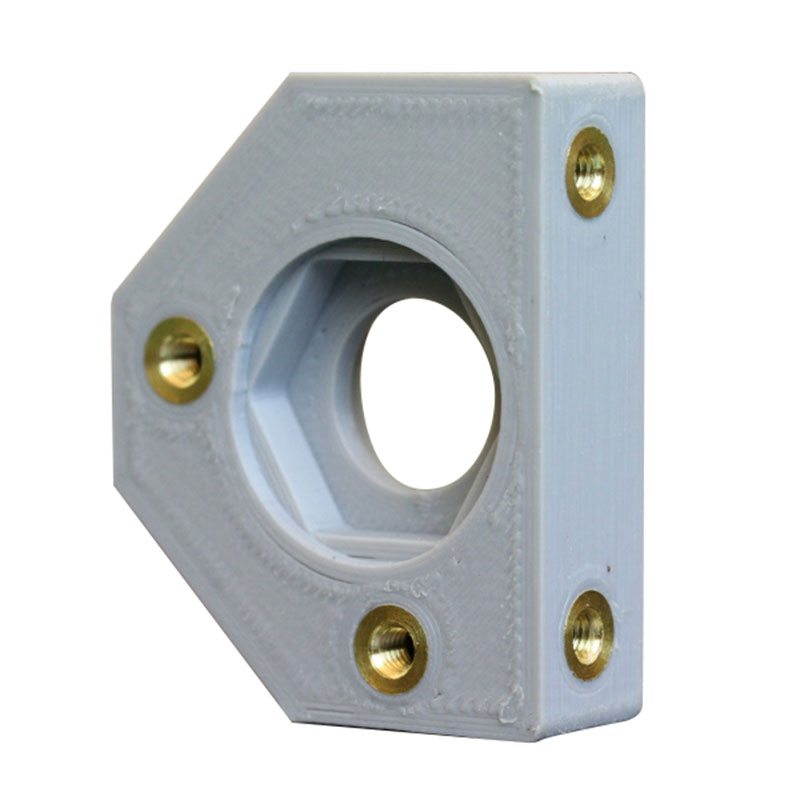

China Polishing Cast Bronze Brass Copper Casting Factory Directly Supply. Guoye Optoelectronics is Polishing Cast Bronze Brass Copper Casting manufacturer and supplier in China.Steel Aerospace Parts Rapid Prototype

Rapid prototype castings are fully functioning parts with the same strength and metallurgical properties as traditionally investment cast parts. However, they carry the added advantage of substituting injected wax patterns with 3-D printed patterns, resulting in a quick and relatively low-cost alternative for those who only need a limited number of parts.

Investment casting using rapid prototypes is a reliable means to quickly produce metal castings while in the preliminary design phases of an investment casting project. This allows you to test out a sample design, which can help avoid expensive tooling changes. Oftentimes, rapid prototype castings are less costly and time-consuming than the process of machining prototypes out of bar stock or producing prototypes through weldments.The following is about Steel Aerospace Parts Rapid Prototype.