China High Precision Medical Device Parts CNC Milling Manufacturers, Suppliers, Factory

We aim to understand high quality disfigurement through the output and supply the most beneficial support to domestic and overseas buyers wholeheartedly for High Precision Medical Device Parts CNC Milling,High Precision Medical Device Products CNC Machining,High Precision Medical Device Components CNC Machining, For additional information and facts, please speak to us as quickly as possible!

High Precision Medical Device Parts CNC Milling, We will continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Hot Products

Auto Parts Heat Treatment Rapid Prototypes

Heat treatments can be applied to metal alloys throughout the manufacturing process. For CNC machined parts, heat treatments are typically applied either:

Before CNC machining: When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining: Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.The following is about Auto Parts Heat Treatment Rapid Prototypes.Highest Level Military Parts Cnc Machining

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.Motorcycles Parts CNC Machining

CNC machines are indispensable for motorcycles simply for the fact that you can create bike parts. People should know that these machines easily create bike parts, which are easily damaged during accidents making them easier to replace. Oftentimes during light crashes, bike parts can be damaged, scratched, crushed, or even brushed against the pavement and in need of replacements.

If you have a damaged bike part and need of a replacement, a CNC Machining motorcycles spare parts would be the desired way to go about it.The following is about motorcycles parts CNC machining.Titanium Aerospace Parts CNC Machining

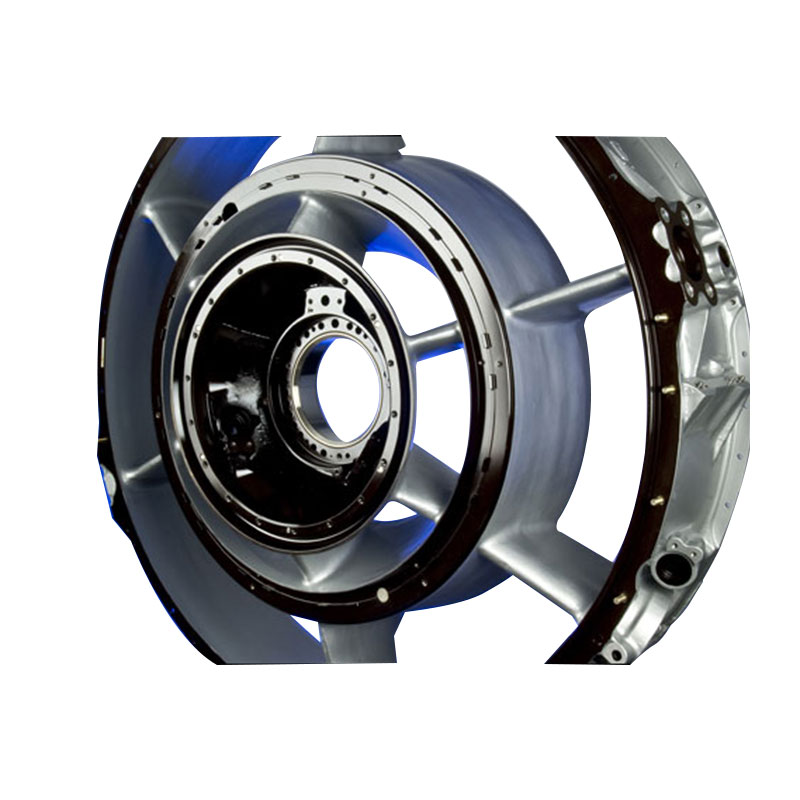

Our high volume components can withstand the intense pressures and various challenges of the Aerospace industry. Common components that we machine for the Aerospace industry include shafts, turbine disks, impellers, and more.The following is about titanium aerospace parts CNC machining.Military Parts Dowel Pins CNC Turning

We carefully consider the dowel pins material to be used as well as the dowel destination. We take into account the ductility of the destination hole and the ductility of the dowel pins material being used to manufacture the machined parts with accurate dimensions. Regarding size and precision, Alpha Omega Swiss manufactures precision dowel pins to exacting tolerances. We can produce dowel pins to a tolerance of +/- .0001 utilizing stainless steel, tool steel, brass, or aluminum.The following is about Military Parts Dowel Pins CNC Turning.Metal Precision Mechanical Parts CNC Machining

Firstly, parts for robotic applications often have a requirement to be strong, tough and lightweight. Materials such as aluminium have ideal characteristics and can easily be machined using CNC Machining.

Similarly POM (also known as Delrin and Acetal) is commonly used for robotic mechanical cnc machining parts. Easy to machine, it is known for its low friction, high stiffness and superior dimensional stability. As a low-cost plastic, it is also a very economical option.The following is about metal precision mechanical parts CNC machining.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy