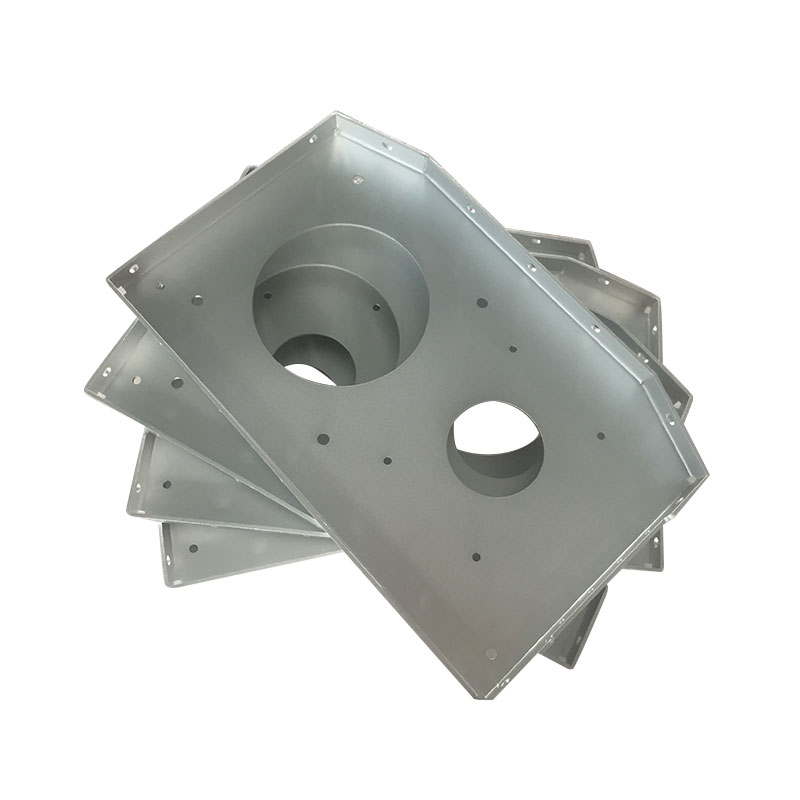

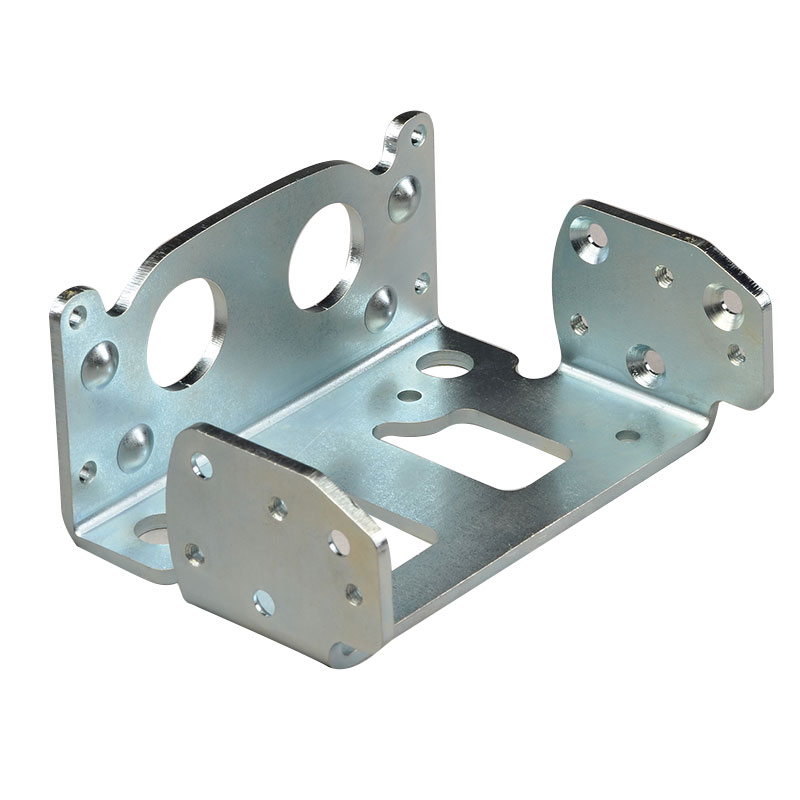

Laser Cutting Aluminium Sheet Metal Parts

Compared to mechanical cutting methods, a laser is easier to work with and there is a reduced possibility of contamination. Laser cutting is also more precise than mechanically cutting since the laser cannot wear down. Furthermore, since lasers use localized heat, there is less chance of warping.The following is about Laser Cutting Aluminium Sheet Metal Parts.

Send Inquiry

Laser Cutting Aluminium Sheet Metal Parts

To cut metal using a laser, a focused laser beam is directed at the material, which is then either melted, burned, vaporized, or blown away by a jet of gas. This cutting method leaves a sleek edge with high quality and a smooth finish.

Compared to mechanical cutting methods, a laser is easier to work with and there is a reduced possibility of contamination. Laser cutting is also more precise than mechanically cutting since the laser cannot wear down. Furthermore, since lasers use localized heat, there is less chance of warping. With advanced technologies and facilities, strict good quality manage, reasonable rate, superior assistance and close co-operation with shoppers, we have been devoted to supplying the very best price for our consumers for Manufacture standard China Engraving Machine Stamping Parts Laser Cutting Aluminium Sheet Metal Parts, We sincerely welcome domestic and foreign retailers who calls, letters inquiring, or to crops to barter, we'll supply you high-quality merchandise as well as the most enthusiastic company,We look forward in your go to and your cooperation. Manufacture standard China Engraving Machine, Bending Parts, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

1.Product Parameter for Laser Cutting Aluminium Sheet Metal Parts

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNC Machining |

510 * 1020 * 500 mm(max) |

+/-0.02 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

|

Clear Anodized |

Polishing |

Zinc plating |

|

Color Anodized |

Passivating |

Oxide black |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

|

Chemical Film |

Laser engraving |

Chrome plating |

|

Brushing |

|

Carburized |

|

Polishing |

|

Hot treatment |

|

Chroming |

|

Powder Coated |

2.Product Feature for Laser Cutting Aluminium Sheet Metal Parts

|

Software |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Material |

Aluminium sheet metal |

|

Surface |

Not rusted and oilded for transport, be free of sharp edges, burrs, and tool marks |

|

Lead time |

500pcs for 7days |

|

Thickness |

0.5mm |

3.Product Details for Laser Cutting Aluminium Sheet Metal Parts

CNC laser metal cutting technology, Shbury produces finished parts and components with smoother surface finishes, and practically burr-free holes and edges, while generating less material waste than conventional stamping processes. Shbury consistently delivers cost-competitive high-quality laser cut parts. Our skilled CNC precision laser cutting metal fabricators process custom sheet metal jobs quickly and accurately. Our CNC laser systems have the latest high-speed axial flow resonators for precision quality cutting of ferrous and non-ferrous metals such as steel and aluminum.

4.Product Application for Laser Cutting Aluminium Sheet Metal Parts

Aluminium sheet metal parts are widely used, and almost

all products that can use metal parts can be used. Such as aerospace products,

auto parts, electronic products, mechanical equipment parts, medical equipment,

defense and military supplies.

5.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7.Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

6.Deliver,Shipping for Mobile Phone Housing Products Vacuum Casting