Sheet Metal

Sheet Metal offers plenty of advantages as compared to both non-metal alternatives and other metal fabrication processes, as well. When compared to machining, sheet metal is much less expensive in both processing and material costs. It does not have the extremely high tooling costs of injection molding, which makes sense at high volumes.

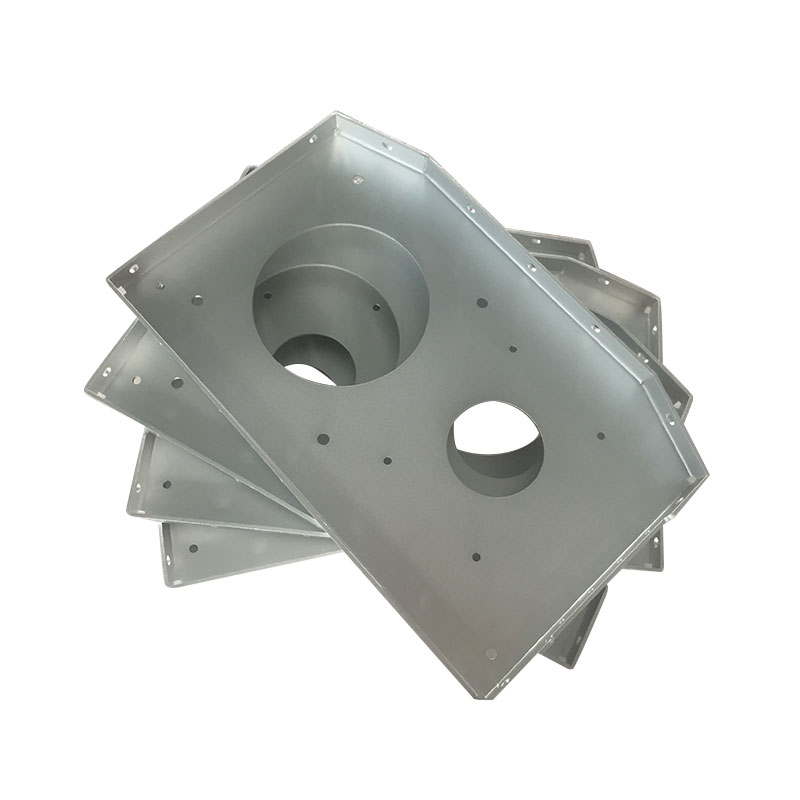

Sheet metal can be cut, stamped, formed, punched, sheared, bent, welded, rolled, riveted, drilled, tapped, machined. Hardware can then be inserted to fix electronic components, metal brackets or other pieces of sheet metal. To finish sheet metal, it can be brushed, plated, anodized, powder-coated, liquid painted, silkscreen, laser-etched, and pad printed. And of course, parts can be welded riveted into complex assemblies.

Shbury as one custom sheet metal manufacturer in China, provide sheet metal parts which used for different applications.

- View as

Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.

Read MoreSend Inquiry