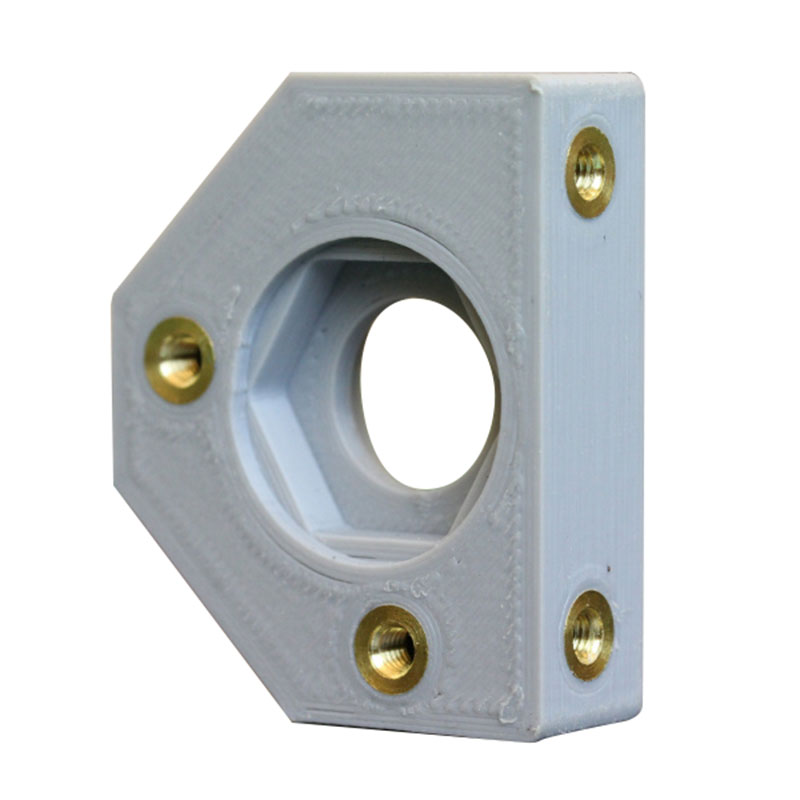

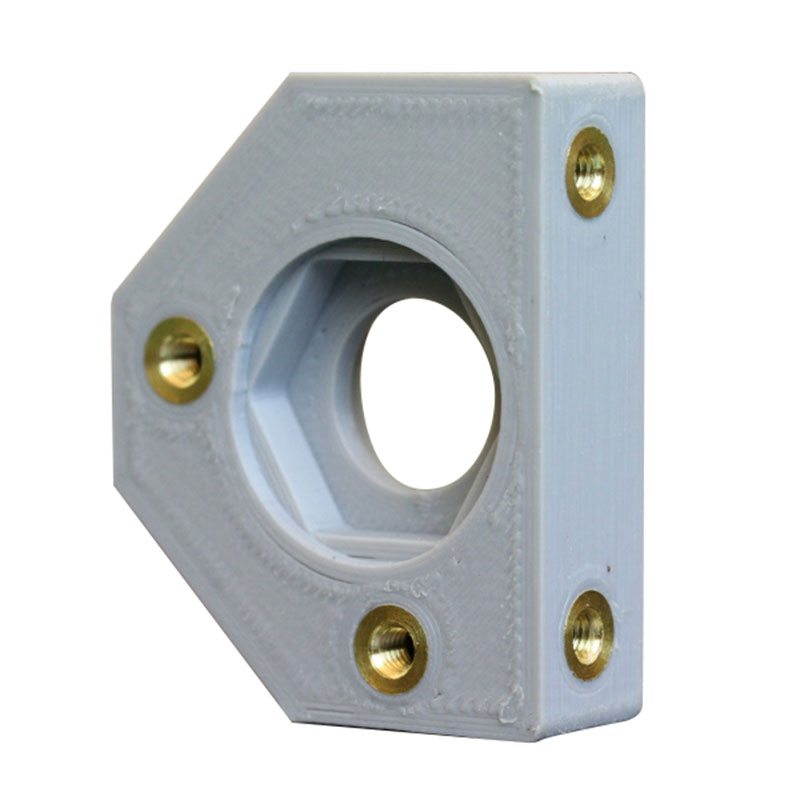

Brass Inserts Plastic Electronic Products Vacuum Casting

Send Inquiry

Brass Inserts Plastic Electronic Products Vacuum Casting

Shbury has a fully equipped Vacuum Casting suite with multiple vacuum casting machines. We also have 3D printing facilities which are used for producing the master pattern. For best quality, we use high definition SLA models.

Because we do everything in-house, including production of the SLA master, the vacuum casting itself, and painting or lacquering to achieve the desired finish, our Project Manager will see your vacuum casting project through each stage of its journey from your initial CAD file through to the final parts and assemblies.

Time to manufacture depends on your desired characteristics. Part size (due to the time required for curing), level of quality and finishing requirement are all key factors.

If you want to insert some metal parts , let the plastic cover the metal also is ok.

When it comes to Vacuum Casting,Shbury has the whole process covered in-house from beginning to end.

1.Product Parameterfor brass inserts plastic electronic products vacuum casting

|

Standard lead time |

Up to 10 copies within 15 working days |

|

Standard accuracy |

±0.3% (with lower limit on ±0.3 mm on dimensions smaller than 100 mm) |

|

Minimum wall thickness |

To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

|

Maximum part dimensions |

The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

|

Typical quantities |

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

|

Surface structure |

High-quality surface finish comparable to injection molding |

2.Product Feature for brass inserts plastic electronic products vacuum casting

What are the main benefits of vacuum casting?

Highly accurate replication of patterns, profiles and textures

Less expensive than hard prototype and production tooling

Fast production

Very high quality

Very fine levels of detail

Wide range of materials/properties including:

Water clear

Flexible polyurethane casting resin grades range

Range of spark texture grades, smooth matt and satin to a high gloss finish

Can be painted and/or lacquered

Parts can be drilled, tapped or have threaded inserts moulded in

Insert the brass, aluminium metal parts

3.Product Details for brass inserts plastic electronic products vacuum casting

Plastic parts and assemblies are becoming more common as engineers work to reduce costs and weight in their designs. But plastics often aren’t strong enough to support fasteners such as screws or bolts. Using screws to attach parts to plastic housings, for example, often ends with stripped threads, failed housings, and assemblies that fall apart.

To get around this limitation, engineers first install threaded metal inserts into plastic parts. They give screws and bolts stronger metal threads to mate with, letting plastic parts be easily assembled, taken apart, and repeatedly reassembled.

That’s why we can insert brass or aluminium or other metal parts to plastic to vacuum casting, if you have any related requirements can contact us.

4.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

5.Deliver,Shipping forbrass inserts plastic electronic products vacuum casting