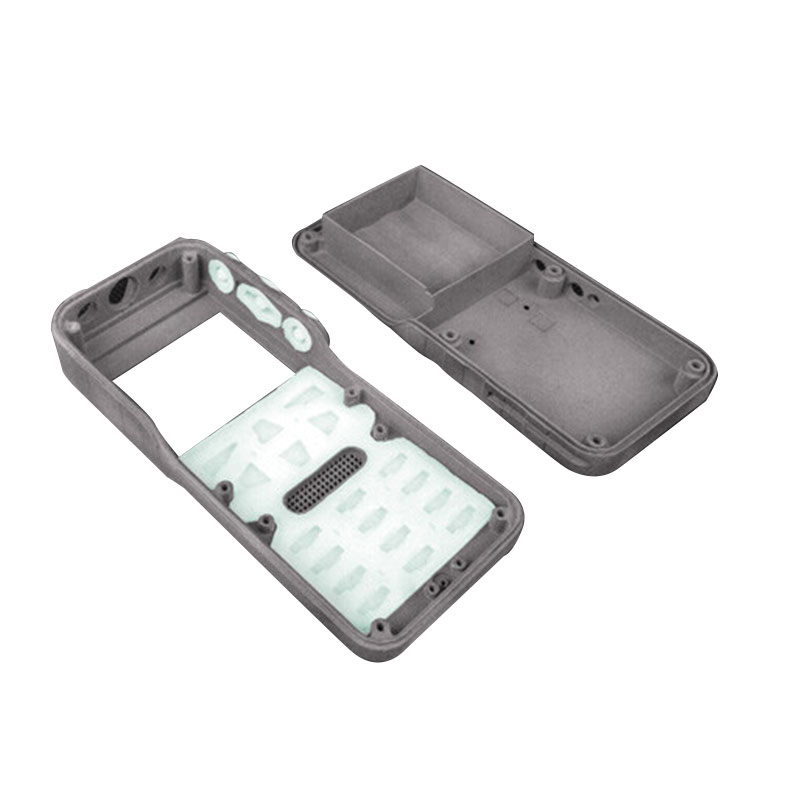

Mobile Phone Housing Products Vacuum Casting

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about mobile phone housing products vacuum casting.

Send Inquiry

Mobile Phone Housing Products Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production Our pursuit and corporation aim should be to "Always satisfy our consumer requirements". We carry on to build and style and design remarkable quality items for both our outdated and new clients and reach a win-win prospect for our clients at the same time as us for Hot sale China Mobile Phone Housing Products Vacuum Casting, We've been sincerely seeking ahead to cooperate with shoppers everywhere in the earth. We consider we are able to satisfy along with you. We also warmly welcome buyers to visit our manufacturing facility and purchase our products. Hot sale China Casting Prototype, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

1.Product Parameterfor Mobile Phone Housing Products Vacuum Casting

|

Standard lead time |

Up to 10 copies within 15 working days |

|

Standard accuracy |

±0.3% (with lower limit on ±0.3 mm on dimensions smaller than 100 mm) |

|

Minimum wall thickness |

To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

|

Maximum part dimensions |

The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

|

Typical quantities |

Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

|

Surface structure |

High-quality surface finish comparable to injection molding |

2.Product Feature for Mobile Phone Housing Products Vacuum Casting

Technical Specifications

1 Standard lead time: Up to 10 copies

within 15 working days

2 Standard accuracy : ±0.3% (with a lower limit on ± 0.3 mm on dimensions

smaller than 100 mm)

3 Minimum wall thickness: To ensure that the mold is filled properly, a wall

thickness of at least 0.75 mm is necessary. For best results, we recommend a

wall thickness of at least 1.5 mm

4 Maximum part dimensions: The size of the mold is limited by the dimensions of

the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product

(maximum volume: 10 liters)

5 Typical quantities: Up to 25 copies per mold (depending on the mold’s

complexity and the casting materials)

6 Surface structure: High-quality surface finish comparable to injection

molding

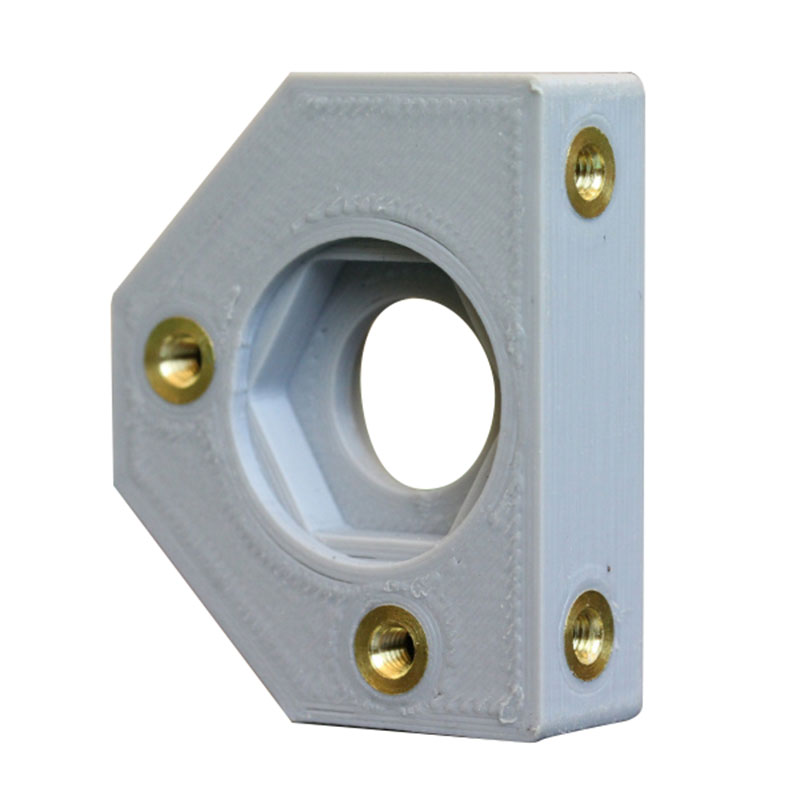

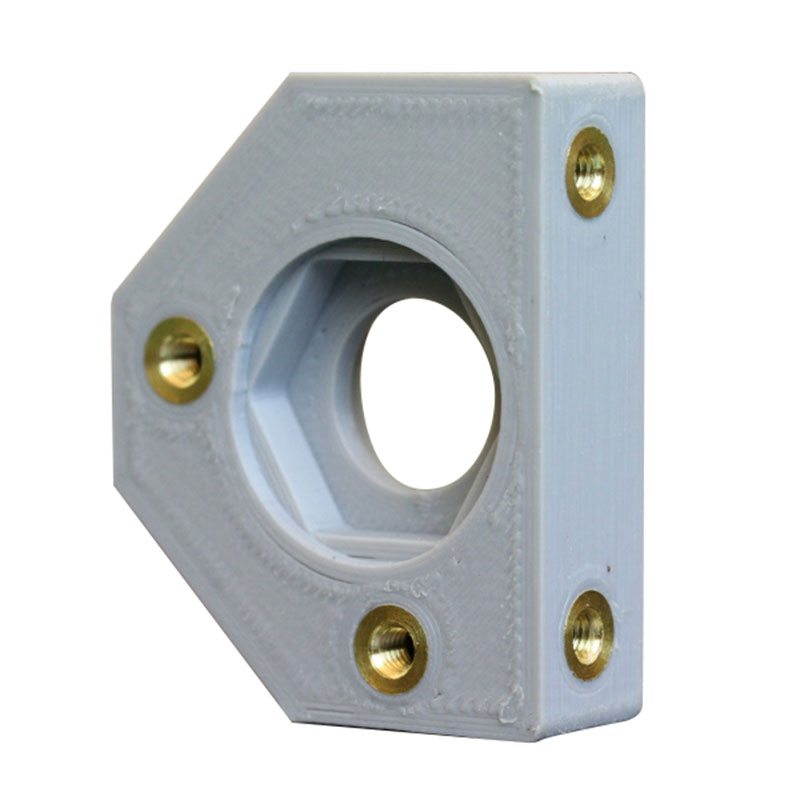

3.Product Details for Smart Mechanical Parts Vacuum Casting

Geometric complexity,accuracy,roughness,cost

Complexity

Vacuum casting has advantages in creating parts with high geometric

complexity. Its is not sensitive to the complexity of the structure, Allow

designers to have unlimited spatial imagination.

Complexity, From high to low

3D Printing > Vacuum casting > CNC Machining > =Injection Molding

Accuracy

ABS, PC, PP, NYLON with a tolerance of +/-0.1mm

TPU/PU/RUBBER with a tolerance of +/-0.3mm

Roughness or Smoothness

From high to low

Injection Molding >= Vacuum casting > CNC Machining > 3D Printing

Cost

Let’s take the part below/image an example,

Material: ABS

Quantity: 20 pieces

Cost from cheap to expensive

3D Printing (USD8/piece)<Vacuum Casting(USD26/piece) < CNC

Machining(USD40/piece)

4.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7.Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

6.Deliver,Shipping for Mobile Phone Housing Products Vacuum Casting