China Auto Hydraulic Valve Components CNC Machining Manufacturers, Suppliers, Factory

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for Auto Hydraulic Valve Components CNC Machining,Auto Hydraulic Valve Parts CNC Milling,Auto Hydraulic Valve Products CNC Machining, If you're searching for a top quality, fast delivery, greatest following company and superior value supplier in China for long-term business partnership, we're going to be your best choice.

Auto Hydraulic Valve Components CNC Machining, With a wide range, good quality, reasonable prices and stylish designs, our goods are extensively used in beauty and other industries. Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Hot Products

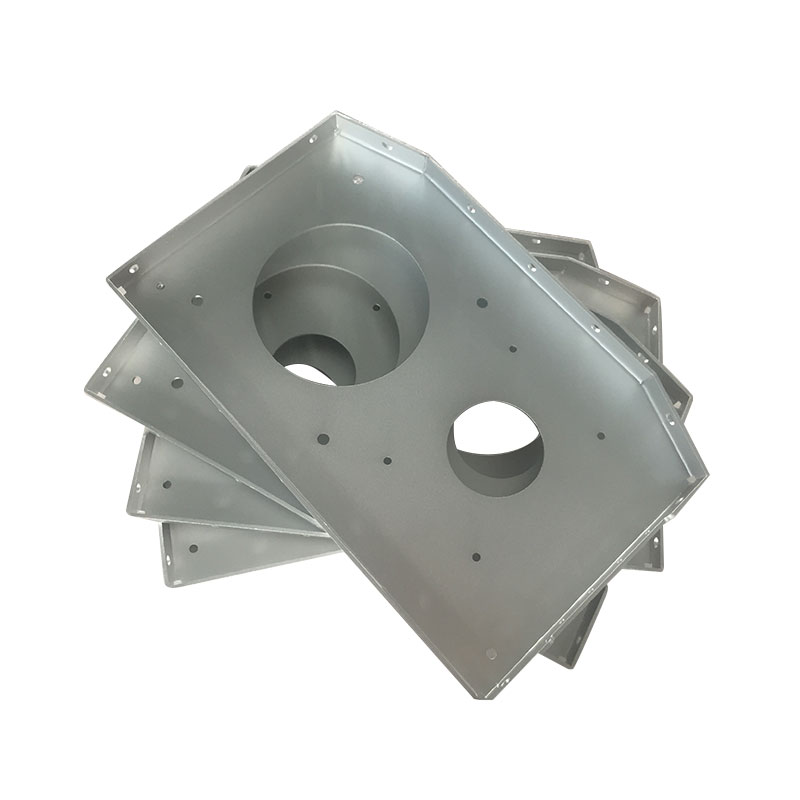

Cold Carbon Steel Sheet Metal Parts

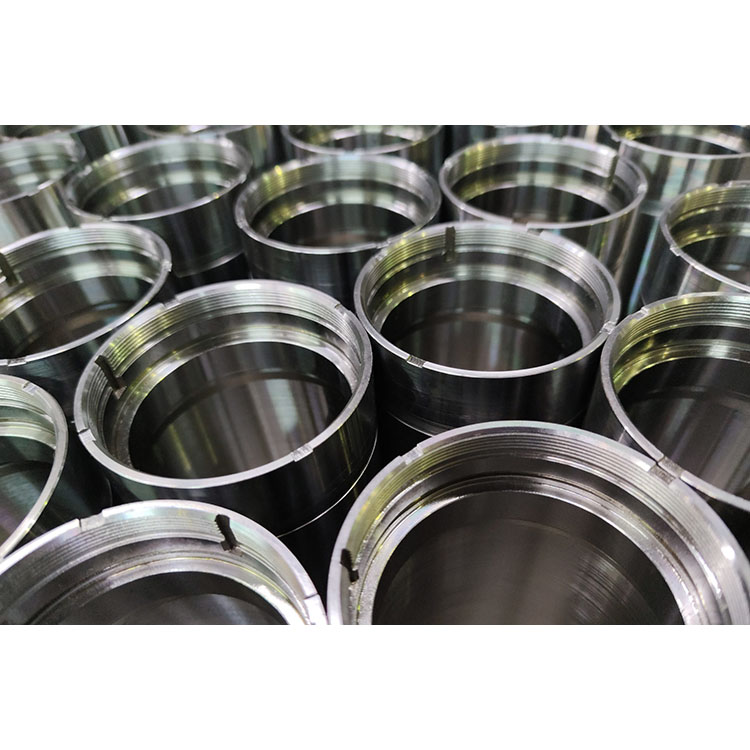

Cold Carbon Steel Sheet Metal PartsElectronic Bushes Products CNC Turning

The following is about Electronic Bushes Products CNC Turning.Auto Solid Valve Housing Parts CNC Machining

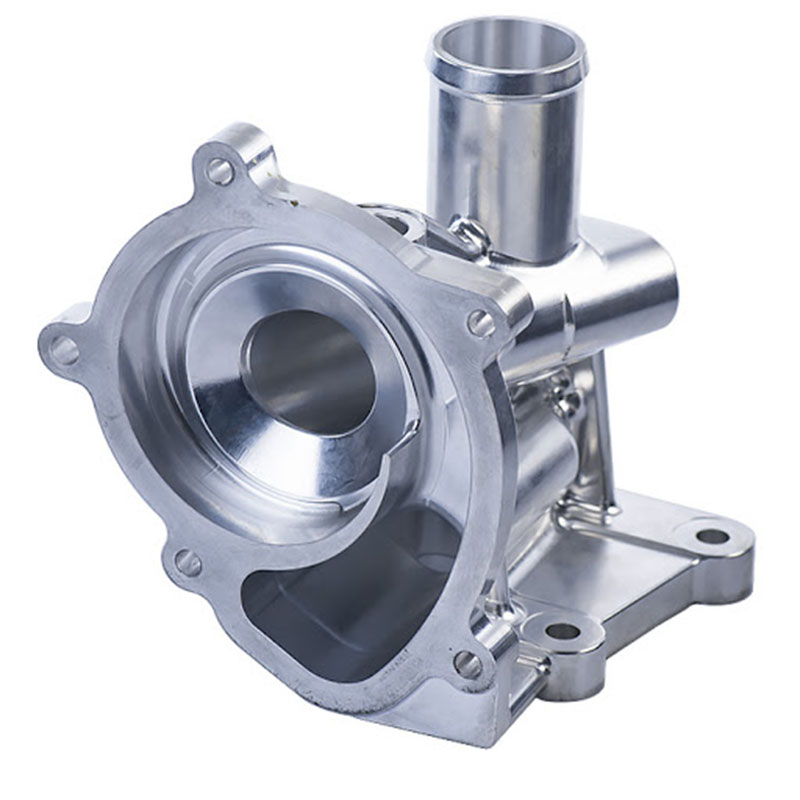

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.Indirectly Human Medical Device Parts CNC Machining

The following is about Indirectly Human Medical Device Parts CNC Machining.Precision Aerospace Parts CNC Machining

Precision aerospace parts CNC machining need durable material, strict specification standard, batch traceability and more requirements to create premium airplane body and parts to ensure excellent performance and definite safety.OEM Precision CNC Machining aluminium Anodizing Spare Parts

OEM Precision CNC Machining aluminium Anodizing Spare Parts:Before we look into aluminum parts anodizing, we should understand the exact meaning and purpose of anodizing. Generally, anodizing is a process through which a layer of metal oxide is electrolytically embedded onto the surface of the pure metal, in this case, Aluminum pars anodizing is like painting but when anodizing, the oxide layer is fully integrated into the underlying metal. Because of this, it can hardly chip or peel. Anodizing is the result of a highly controlled oxidation process that converts the surface of the metal into a corrosion-resistant, durable cover.