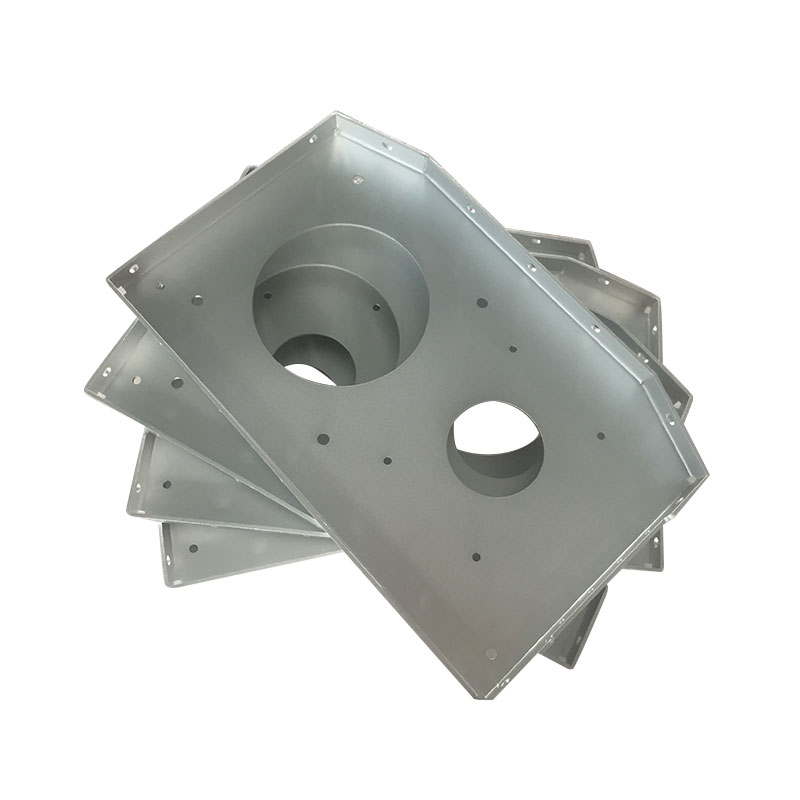

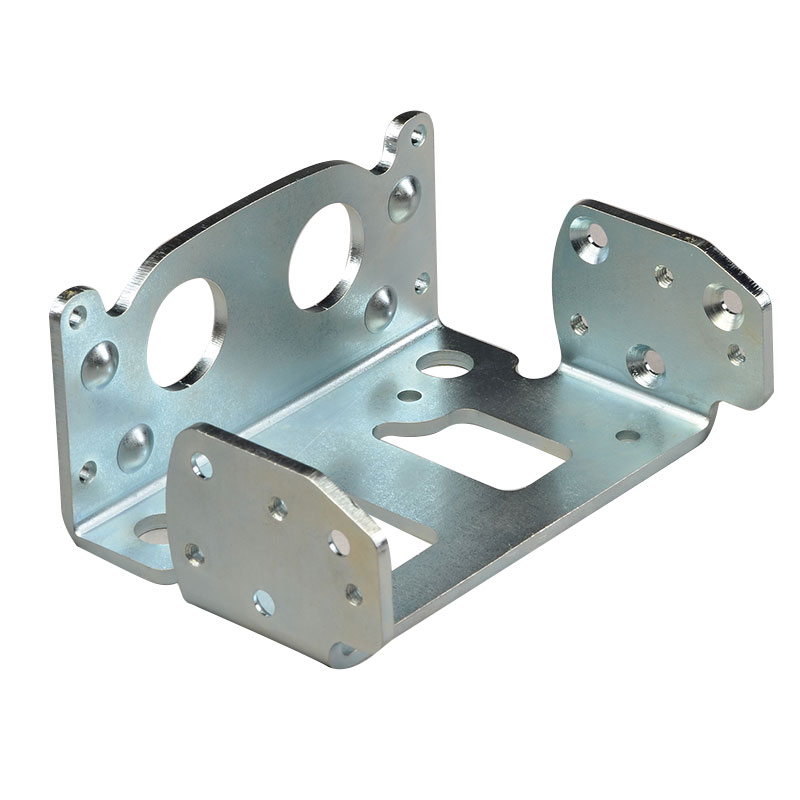

OEM Precision CNC Machining aluminium Anodizing Spare Parts

Send Inquiry

OEM Precision CNC Machining aluminium Anodizing Spare Parts

How is Aluminum Anodized for your aluminum spare parts?

Before we look into aluminum parts anodizing, we should understand the exact meaning and purpose of anodizing. Generally, anodizing is a process through which a layer of metal oxide is electrolytically embedded onto the surface of the pure metal, in this case, Aluminum pars anodizing is like painting but when anodizing, the oxide layer is fully integrated into the underlying metal. Because of this, it can hardly chip or peel. Anodizing is the result of a highly controlled oxidation process that converts the surface of the metal into a corrosion-resistant, durable cover. The process of anodizing begins by immersing various aluminum parts into a series of solutions that all have specific purposes. Before the anodizing process, the aluminum parts are thoroughly cleaned by passing them through a water-based solution with mild acids, alkaline, or detergents. After the cleaning, they are passed through a pretreatment phase that utilizes caustic etch, this further enhances the metal’s brightness to give it a shiny finish. The anodizing process takes advantage of an aluminum substrate that is composed of aluminum oxide. Anodizing is effected by immersing the aluminum parts into an acid electrolyte bath which can either be sulphuric, phosphoric, or chromic acid. The aluminum is then connected as an anode to a complete circuit and a cathode is also introduced into the solution so that there is a complete flow of electrical current. During this flow, the acid-based electrolyte releases its oxygen ions which combine with the negative aluminum ions at the anode ( which is the surface of the aluminum metal) to form an invasive coating of a transparent but microscopically porous layer of aluminum oxide, thus anodizing. Anodizing is like enhancing a natural phenomenon while controlling the thickness of the oxide layer using the levels of the electric current and the exposure time of the metal to the process.

1.Product Parameter for OEM Precision CNC Machining aluminium Anodizing Spare Parts

Capacity

|

CNC Turning |

φ0.5 - φ300 * 750 mm |

+/-0.005 mm |

|

CNC Machining |

510 * 1020 * 500 mm(max) |

+/-0.02 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

|

Plastic |

ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

|

titanium |

TC4 ,GR5 , Ti6AL4V |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

Plastic |

|

Clear Anodized |

Polishing |

Zinc plating |

Plating |

|

Color Anodized |

Passivating |

Oxide black |

Painting |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

polishing |

|

Chemical Film |

Laser engraving |

Chrome plating |

Laser engraving |

|

Brushing |

|

Carburized |

|

|

Polishing |

|

Hot treatment |

|

|

Chroming |

|

Powder Coated |

|

2.Product Feature for OEM Precision CNC Machining aluminium Anodizing Spare Parts

|

Software |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Material |

aluminium |

|

Surface |

Red anodizing |

|

Lead time |

200pcs for 7days |

|

Application |

Auto spare parts |

|

MOQ |

1piece |

3.Product Details for OEM Precision CNC Machining aluminium Anodizing Spare Parts

What is hard anodizing?

Hard anodizing / Hard coating is the application of

a highly resistant layer of pure aluminum oxide which further makes the

aluminum surface as hard as steel. This made possible by the greater thickness

and weight of the resulting layer. Nevertheless, it can only be carried out on

an un-anodized aluminum surface. Hard anodizing makes a metal more resistant to

corrosion and because of the enhanced insulation, it can not conduct any

electricity or heat, for this reason, hard-coated aluminum parts are intended

for use, and preferred for parts that endure extreme temperatures and highly

corrosive applications.

How can color be added to aluminum parts anodizing?

Anodized aluminum parts can be colored to produce a cleaner and finer finish. There are 4 ways by which this can be done, these include: – Using a dye. The freshly anodized aluminum can be immersed in a colored liquid solution with a concentrated dye, the oxide coating will absorb the dye permanently. The intensity of the color depends on the concentration of the dye, the temperature of the solution, and the time of immersion.

– Electrolytic coloring. This involves immersing the anodized aluminum parts into a bath containing some inorganic metals. A current is then supplied to the solution and the metal salts are deposited at the base of the pores. The resulting color will depend on the metal used.

– Integral coloring. Integral coloring involves simultaneous anodizing and coloring in a single step process. Various metals like bronze, tin, and cobalt can be used together with a dye to bring out the final effects. This also results in a more abrasive resistant finish.

– Inference coloring. Inference coloring involves the modification of the pore structures using metal deposition which produces light colors ranging from blue, green, yellow, and red. These are as a result of optical interference.

4.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A6:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A8:Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

5.Deliver,Shipping forCNC Precision Titanium Parts Machining