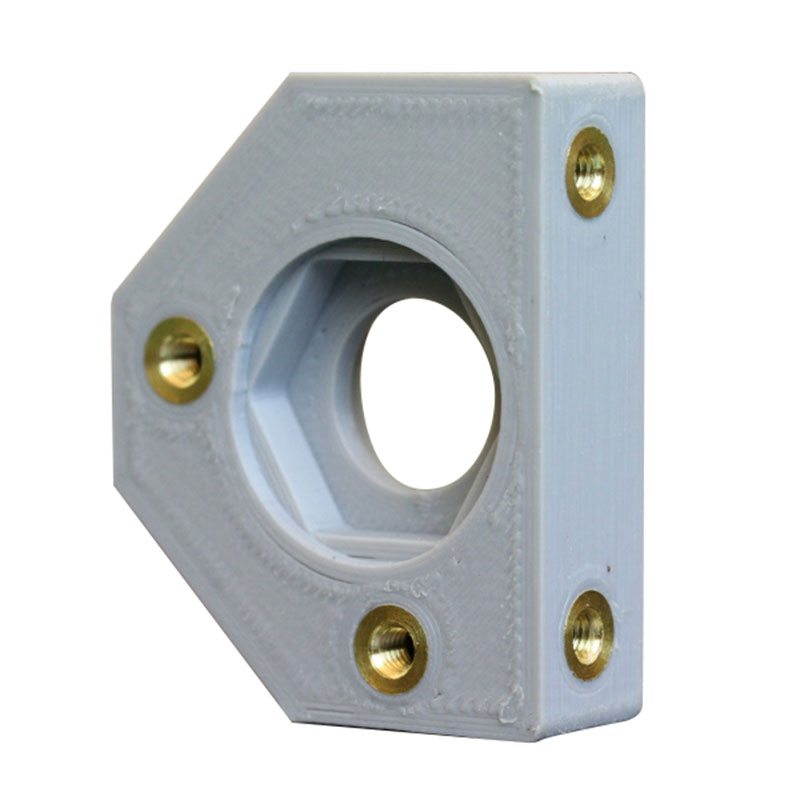

China CNC Precision Machining Iridate Aluminum Sensor Housing Manufacturers, Suppliers, Factory

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for CNC Precision Machining Iridate Aluminum Sensor Housing,Auto Sensor Housing Parts CNC Milling,Auto Sensor Housing Products CNC Machining,Auto Sensor Housing Components CNC Machining,Precision CNC Machining Parts, Aluminum Housing, We're incredibly proud with the excellent name from our shoppers for our products' trustworthy quality.

CNC Precision Machining Iridate Aluminum Sensor Housing, Our merchandise have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Hot Products

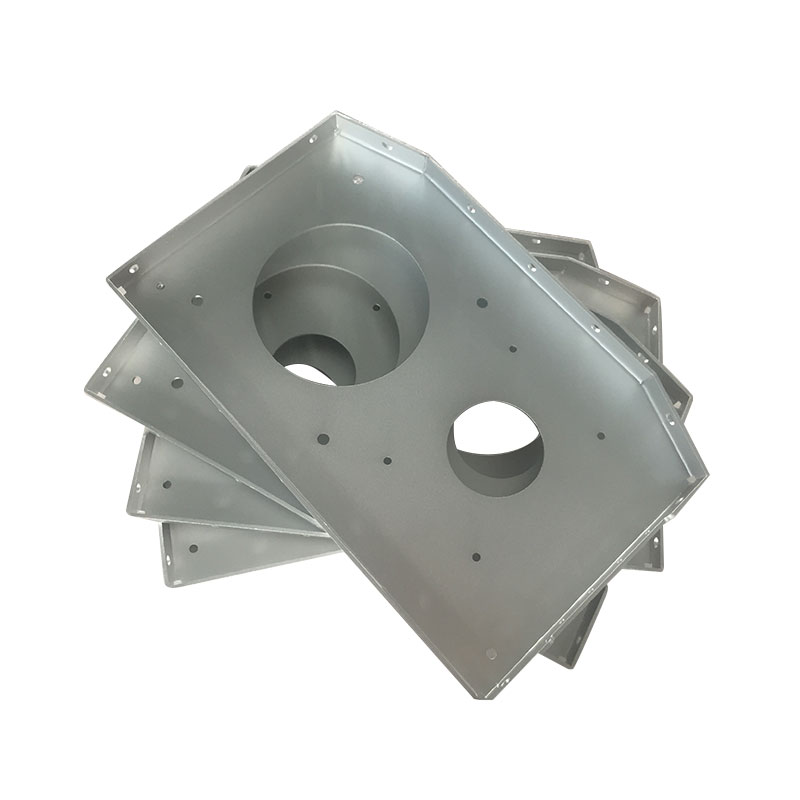

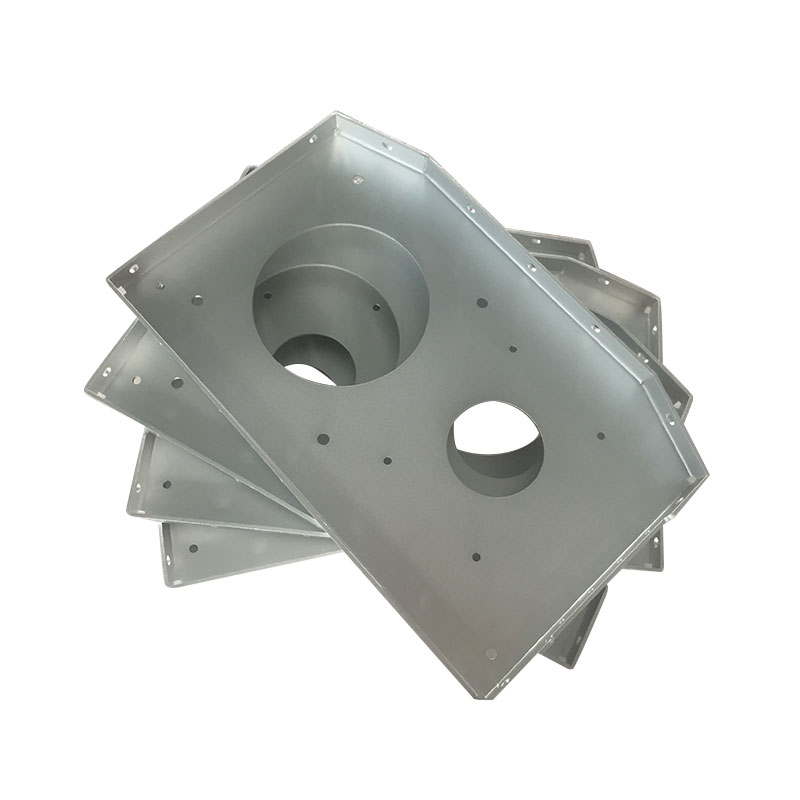

Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.Auto Pipe Joint Parts CNC Machining

One of the top CNC machining service suppliers in Shbury Tech, has been specialized in producing custom CNC turning pipe joints (expansion, welding, clamp) for automobile industry for over 10 years with superior quality and OEM service. Our products of CNC turned and machined pipe joint include zinc, iron, aluminum pipe joint, metal pipe joint, steel, stainless steel, brass pipe joint and other types of CNC lathe machine pipe joint. Reliable auto pipe joints are supplied to consumers with high-precision and stable quality and competitive prices.The following is about auto pipe joint parts CNC machining.Stainless Steel Aerospace Parts CNC Machining

CNC machinery can operate with even the highest-quality metals, creating parts that can withstand the intense pressures and temperatures inherent to aerospace applications,especially stainless steel aerospace parts CNC Machining. We at Shbury are deeply aware of the many benefits CNC machining brings to the aerospace manufacturing field, which is why we’ve made this manufacturing technique central to our production processes.Computer Housing Products CNC Machining

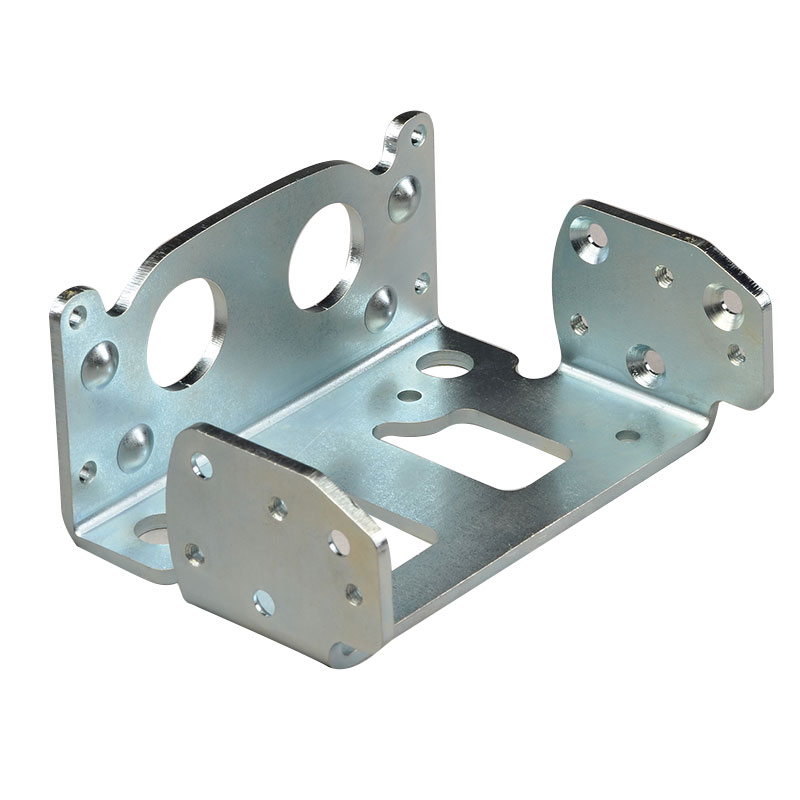

The following is about Computer Housing Products CNC Machining.Accurate Mechanical Parts CNC Machining

The following is about accurate mechanical parts CNC machining.Indirectly Human Medical Device Parts CNC Machining

The following is about Indirectly Human Medical Device Parts CNC Machining.