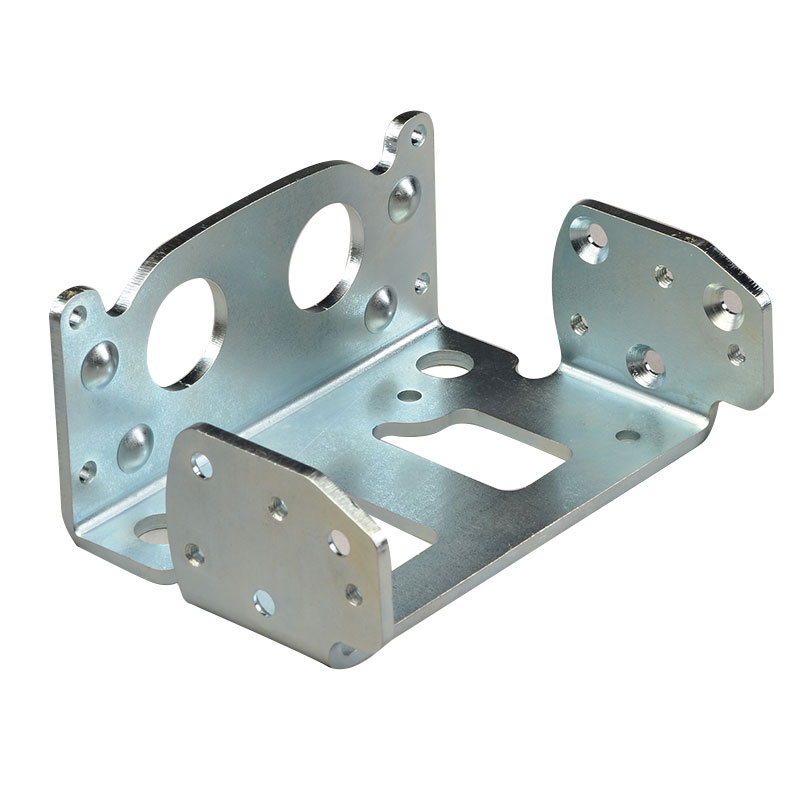

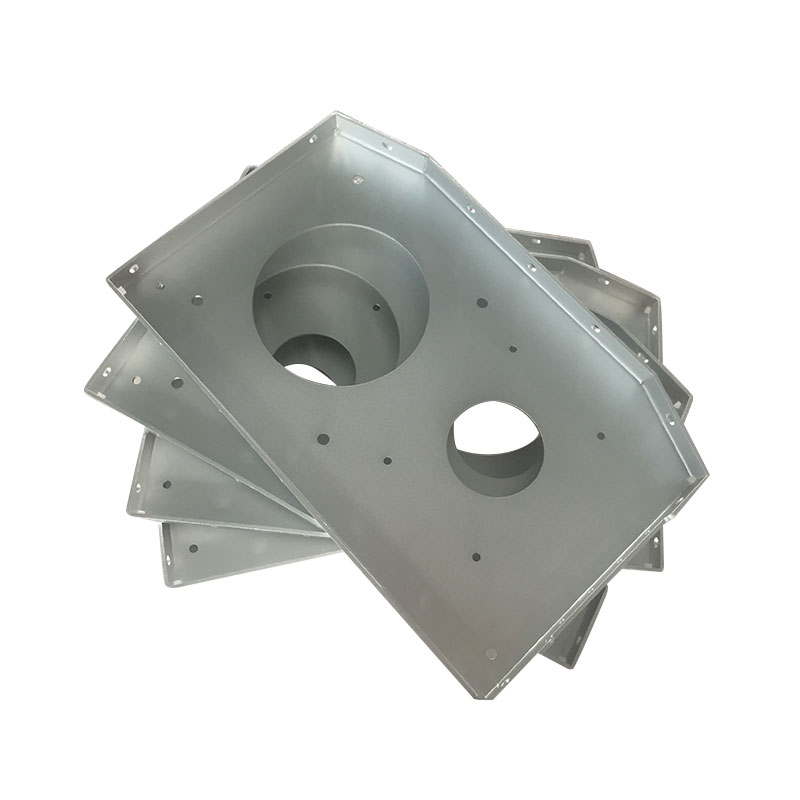

Auminium Sheet Metal Stamping Parts

At Shbury we don’t take a cookie-cutter approach to any of our partnerships. Our tooling is completely customized and we’re able to meet your exact manufacturing needs through extensive list of value added services.The following is about auminium sheet metal stamping parts.

Send Inquiry

Auminium Sheet Metal Stamping Parts

Take your custom products to the next level with high-grade aluminum sheet metal stampings parts from Shbury. We’re an aluminum stamping factory that will support your vision by providing custom aluminum parts tailored to your unique project. Thanks to our industry-leading in-house tooling capabilities and favorable lead times, you can trust that we will deliver on time and on budget.carry on to improve, to ensure merchandise quality in line with market and shopper standard prerequisites. Our firm has a high quality assurance program are actually established for Factory For China OEM ODM Precisionl Auminium Sheet Metal Stamping Parts, As an experienced group we also accept tailored orders. The main target of our organization would be to build up a satisfying memory for all clients, and build a long-term win-win organization relationship. Factory For China CNC Machined Parts, Auminium Sheet Metal Stamping Parts, Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality solutions and service.Thanks.

At Shbury we don’t take a cookie-cutter approach to any of our partnerships. Our tooling is completely customized and we’re able to meet your exact manufacturing needs through extensive list of value added services.

1.Product ParameterforAuminium Sheet Metal Stamping Parts

Capacity

|

CNC Stamping |

1000 * 1000 mm(max) |

+/-0.05 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

|

Thickness |

From 0.1 to 5mm |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

|

Clear Anodized |

Polishing |

Zinc plating |

|

Color Anodized |

Passivating |

Oxide black |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

|

Chemical Film |

Laser engraving |

Chrome plating |

|

Brushing |

|

Carburized |

|

Polishing |

|

Hot treatment |

|

Chroming |

|

Powder Coated |

2.Product Feature forAuminium Sheet Metal Stamping Parts

|

Software |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

Material |

Aluminium sheet metal |

|

Surface |

Not rusted and oilded for transport, be free of sharp edges, burrs, and tool marks |

|

Lead time |

500pcs for 7days |

|

Thickness |

0.5mm |

3.Product Details forAuminium Sheet Metal Stamping Parts

1100 Aluminum – A strong alloy, considered “commercially pure” aluminum. It features high electrical conductivity, advanced corrosion resistance, and easy work-ability.

2024 Aluminum – Alloyed with copper for applications that require high strength-to-weight ratio and strong fatigue resistance.

3003 Aluminum – A general purpose alloy commonly used in sheet metal applications including siding, roofs and gutters.

5052 Aluminum – Alloyed with chromium and magnesium, often used for aircraft, architecture and street lighting.

6061 Aluminum – Precipitation-hardened alloy containing magnesium and silicon. It features good weld-ability and is commonly used for extruded products.

4.Product Application for Auminium Sheet Metal Stamping Parts

Aluminium sheet metal parts are widely used, and almost all products that can

use metal parts can be used. Such as aerospace products, auto parts, electronic

products, mechanical equipment parts, medical equipment, defense and military

supplies.

5.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7.Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

6.Deliver,Shipping for Mobile Phone Housing Products Vacuum Casting