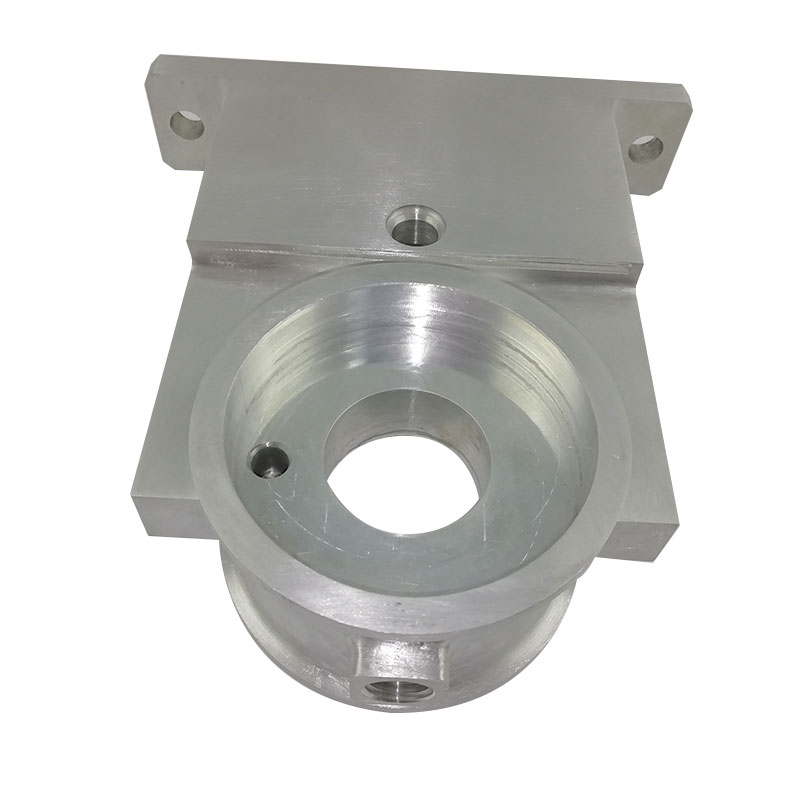

China Motorcycles Parts CNC Milling Manufacturers, Suppliers, Factory

In the past few years, our firm absorbed and digested highly developed technologies equally at home and abroad. Meanwhile, our business staffs a group of experts devoted on the growth of Motorcycles Parts CNC Milling,Motorcycles Products CNC Machining,Motorcycles Components CNC Machining,CNC Machining Aluminum Parts CNC Machining,Magnesium CNC Machining Parts, We warmly welcome all intrigued clients to call us for additional details.

Motorcycles Parts CNC Milling, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal products. In his way, We can enrich our life style and promote a better living environment for the global community.

Hot Products

Auto Parts Heat Treatment Rapid Prototypes

Heat treatments can be applied to metal alloys throughout the manufacturing process. For CNC machined parts, heat treatments are typically applied either:

Before CNC machining: When a standardized grade of a metal alloy is requested that is readily available, the CNC service provider will machine the parts directly from that stock material. This is often the best option for reducing lead times.

After CNC machining: Some heat treatments significantly increase the hardness of the material or are used as a finishing step after forming. In these cases, the heat treatment is applied after CNC machining, as high hardness reduces the machinability of a material. For example, this is standard practice when CNC machining tool steel parts.The following is about Auto Parts Heat Treatment Rapid Prototypes.Cold Rolled Steel Sheet Metal Parts

Cold Rolled Steel Sheet Metal Parts have been available for many, many years, and have been successfully used for a multitude of applications. Today's Cold Rolled Steel Sheet Metal Parts are much improved over those used in the past. They offer better control of thickness, shape, width, surface finish, and other special quality features that compliment the emerging need for highly engineered end use applications.Medical Device Plastic Housing Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about medical device plastic housing vacuum casting.2021 New Design Red Anodizing Aluminum CNC Machining Service

2021 New Design Red Anodizing Aluminum CNC Machining Service, Aluminum CNC parts are the all-time preferred auto components for auto spares and other industries, not just because they are very lightweight and attractive, but also because aluminum has many additional properties like its durability and its ease of installation. Under specific conditions, aluminum can be made very corrosion resistant. The fact that this metal can be cheaply obtained makes it the most economical option for the manufacturing industry. Aluminum parts anodizing is a process that makes aluminum the ultimate metal for a lot of interior and exterior building purposes and designs. Aluminum can also be molded into different shapes to form various aluminum parts.PEEK Auto Parts Rapid Prototyping

The following is about PEEK Auto Parts Rapid Prototyping.Agricultural Machinery Parts CNC Machining

Agricultural Industry is ever evolving, one thing hasn’t changed at all: agricultural equipment component failure can have major implications for a project or a crop. Since agriculture parts are large and complex, all agriculture parts which are used on the agricultural equipment must be carefully worked with high demands of technical specifications including tight tolerance, ultra-high precision specifications, and the best durable materials to ensure the machines and equipment’ service life. So customized CNC machining services for agricultural equipment is very important in the agriculture parts manufacturing field, also custom CNC agricultural parts can make your equipment more competitive in the market.The following is about agricultural machinery parts CNC machining.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy