China PEEK Auto Components Rapid Prototyping Manufacturers, Suppliers, Factory

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of PEEK Auto Components Rapid Prototyping,PEEK Auto Products Rapid Prototyping, Looking to the long run, a lengthy way to go, regularly striving to become the all employees with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced merchandise, good quality first-class modern company and work hard!

PEEK Auto Components Rapid Prototyping, Upon today, now we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to offer the highest quality solutions with best price. We are looking forward to doing business with you!

Hot Products

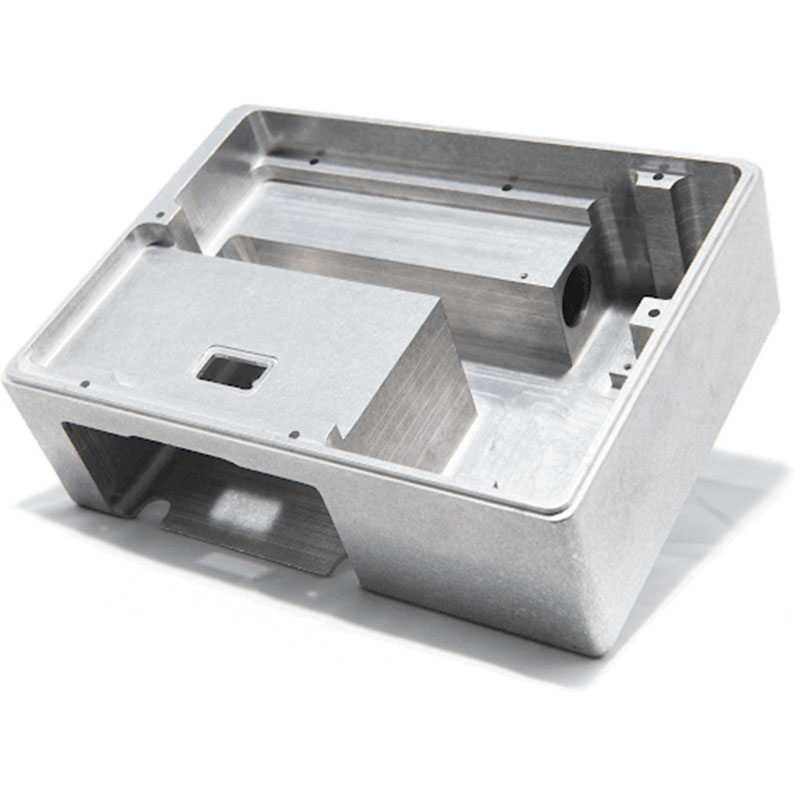

Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.OEM Precision CNC Machining aluminium Anodizing Spare Parts

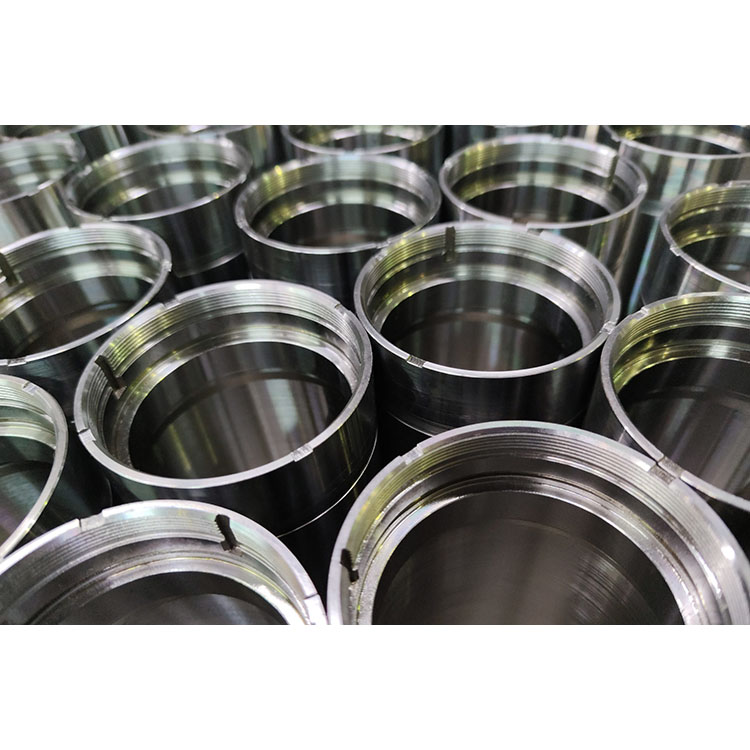

OEM Precision CNC Machining aluminium Anodizing Spare Parts:Before we look into aluminum parts anodizing, we should understand the exact meaning and purpose of anodizing. Generally, anodizing is a process through which a layer of metal oxide is electrolytically embedded onto the surface of the pure metal, in this case, Aluminum pars anodizing is like painting but when anodizing, the oxide layer is fully integrated into the underlying metal. Because of this, it can hardly chip or peel. Anodizing is the result of a highly controlled oxidation process that converts the surface of the metal into a corrosion-resistant, durable cover.Mechanical Retainer Rings CNC Turning

The following is about Mechanical Retainer Rings CNC Turning.Office Industry Parts Rapid Prototypes

Rapid prototyping uses 3D computer aided design (CAD) and manufacturing processes (typically additive manufacturing) to quickly develop 3D parts, models, or assemblies for research and development and/or product testing.

The use of rapid prototyping techniques allows design teams to develop multiple iterations of a design prototype without the added cost and time using traditional manufacturing and design techniques.The following is about Office Industry Parts Rapid Prototypes.Mechanical Connectors Parts CNC Turning

Mechanical Connectors Parts, including the Joint Connector Nuts, Joint Connector Blots, Joint Connector Screws, are mechanical connectors which used to link between two structures, connect parts or components together similar to fasteners.The following is about Mechanical Connectors Parts CNC Turning.Airframe Plastic Parts Vacuum Casting

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.