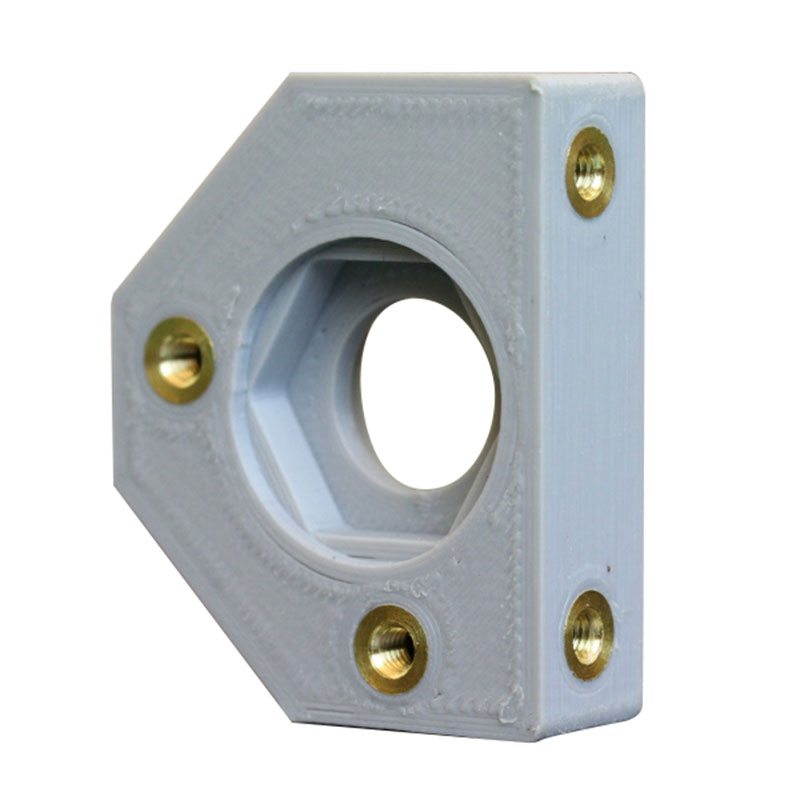

China Precision Injection Molding Brass Inserts Nut Manufacturers, Suppliers, Factory

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for Precision Injection Molding Brass Inserts Nut,Polishing Cast Bronze Brass Copper Casting,Pipe Fittings PVC Elbow Inserts Brass,Plug Inserts with Hollow Brass Pins Plastic,Electrical Brass Fuse Cutout Parts, We give priority to good quality and customer fulfillment and for this we follow stringent excellent control measures. We've in-house testing facilities where our goods are tested on each and every aspect at different processing stages. Owning to latest technologies, we facilitate our prospects with custom-made production facility.

Precision Injection Molding Brass Inserts Nut, Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to provide our customers more profit, and looking forward to more chance to make business.

Hot Products

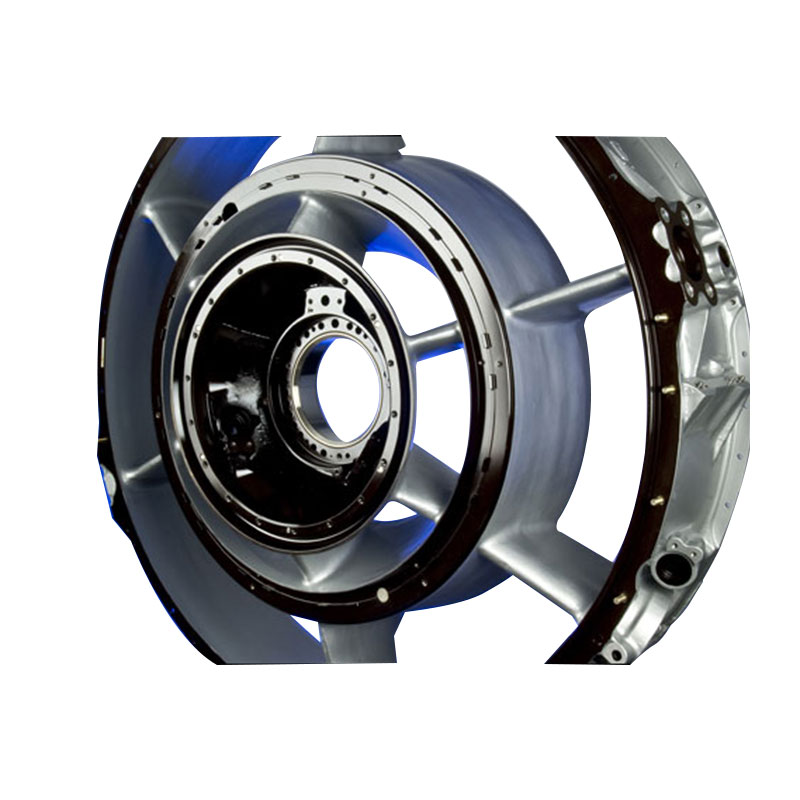

Aluminium Anodizing Military Parts CNC Turning

The Aluminium Anodizing Military Parts CNC Turning provided by Shbury are made of 6061 aluminum using CNC milling, turning and drilling machines for a variety of equipment. Our precision machining services have the ability to upgrade your current design to solid piece with the exact specification, also ensure consistent quality and short lead time for your custom prototype and low/high volume production parts. Black anodizing process is applied on the Aluminium Anodizing Military Parts CNC Turning, which increases the thickness of the natural oxide layer on the surface of aluminum components, and improves its corrosion and wear resistance. Our aluminum anodizing services provide an anodized aluminum coating that meets industry standards. Other colors can be dyed during the process. More surface treatment services available to give your aluminum drilling parts or milling parts a smooth surface finish.Airframe Plastic Parts Vacuum Casting

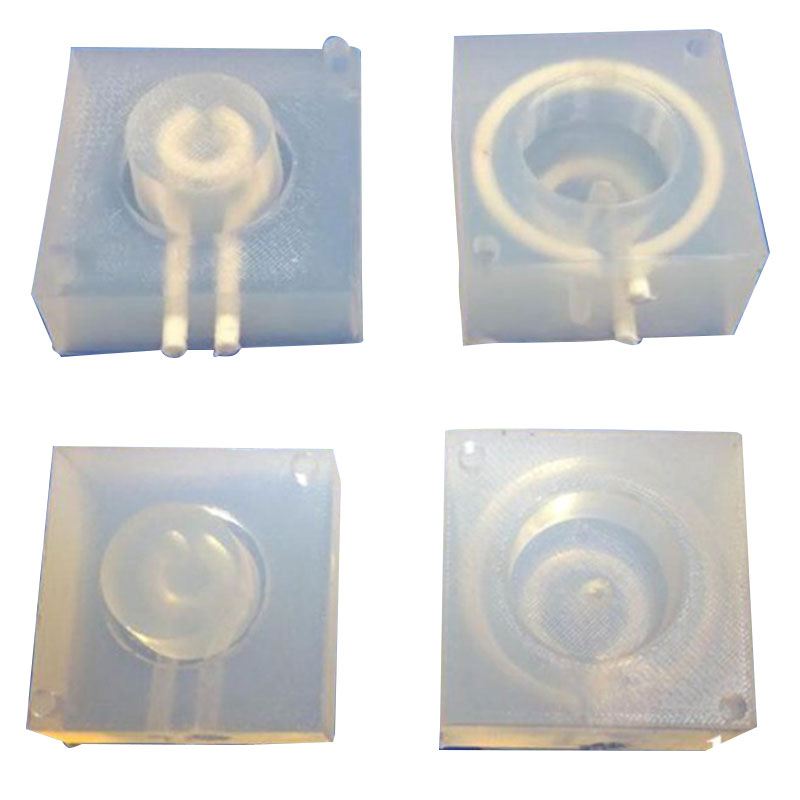

Advantages of Vacuum Casting Technology Possibility of casting parts of complicated shapes, thin-wall parts or parts with negative bevels. Production of small series of prototype or final parts (from dozens up to hundreds of pieces). Favourable production costs in comparison with plastic injection moulding – the production of metal moulds is unnecessary. Fast production – a matter of days. The accuracy of production is comparable with the accuracy of parts manufactured by plastic injection moulding. A wide range of possibilities for final surface treatment.The following is about Airframe Plastic Parts Vacuum Casting.Auto Solid Valve Housing Parts CNC Machining

Valve Housing is a key auto valve fitting to assist valve to control the flow of air or liquid through the tube. If your valve in a corrosive environment and the valve housing can't resist corrosion, it will reduce the durability.The inappropriate valve housing and valve fittings will influence valve performance as well.

So, choosing the right valve housing and valve seal material is critical to the running of an automobile valve and the whole system. The core characteristics, materials, properties of the automotive valve housing and application environment should be taken into consideration, including temperature, corrosion possibility, wear characteristics and pressure.The following is about auto solid valve housing parts CNC machining.Auto Oil And Gas Rubber Parts Vacuum Casting

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.Auto Pipe Joint Parts CNC Machining

One of the top CNC machining service suppliers in Shbury Tech, has been specialized in producing custom CNC turning pipe joints (expansion, welding, clamp) for automobile industry for over 10 years with superior quality and OEM service. Our products of CNC turned and machined pipe joint include zinc, iron, aluminum pipe joint, metal pipe joint, steel, stainless steel, brass pipe joint and other types of CNC lathe machine pipe joint. Reliable auto pipe joints are supplied to consumers with high-precision and stable quality and competitive prices.The following is about auto pipe joint parts CNC machining.Aluminium Mechanical CNC Machining Parts Anodizing

It's a CNC mill work for aluminium anodizing parts. After cnc machining is complete the part is anodized blue.

Unlike most other finishes, anodizing preserves the natural luster, texture, and beauty of the metal itself. The anodized coating is hard, durable, will never peel, and, under normal conditions, will never wear through. Anodizing is a process for finishing aluminum alloys that employs electrolytic oxidation of the aluminum surface to produce a protective oxide coating. The anodic coating consists of hydrated aluminum oxide and is considered resistant to corrosion and abrasion. Conventional coatings are 0.1 to 1.0 mil thick and are essentially transparent but they may be colored like sample above.The following is about Aluminium Mechanical CNC Machining Parts Anodizing.