Products

- View as

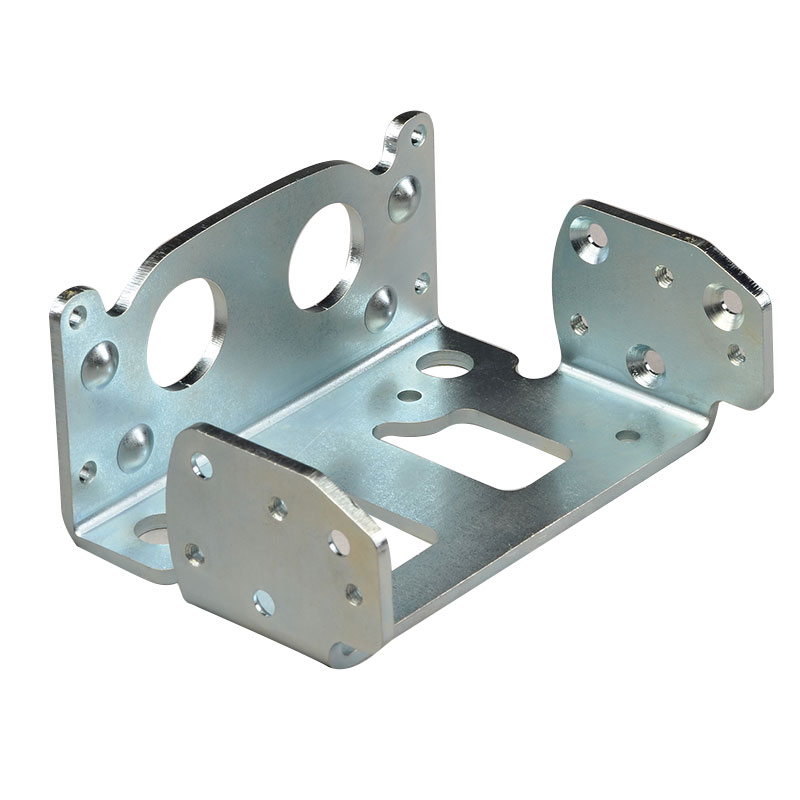

Auminium Sheet Metal Stamping Parts

Take your custom products to the next level with high-grade aluminum sheet metal stampings parts from Shbury. We’re an aluminum stamping factory that will support your vision by providing custom aluminum parts tailored to your unique project. Thanks to our industry-leading in-house tooling capabilities and favorable lead times, you can trust that we will deliver on time and on budget.

At Shbury we don’t take a cookie-cutter approach to any of our partnerships. Our tooling is completely customized and we’re able to meet your exact manufacturing needs through extensive list of value added services.The following is about auminium sheet metal stamping parts.

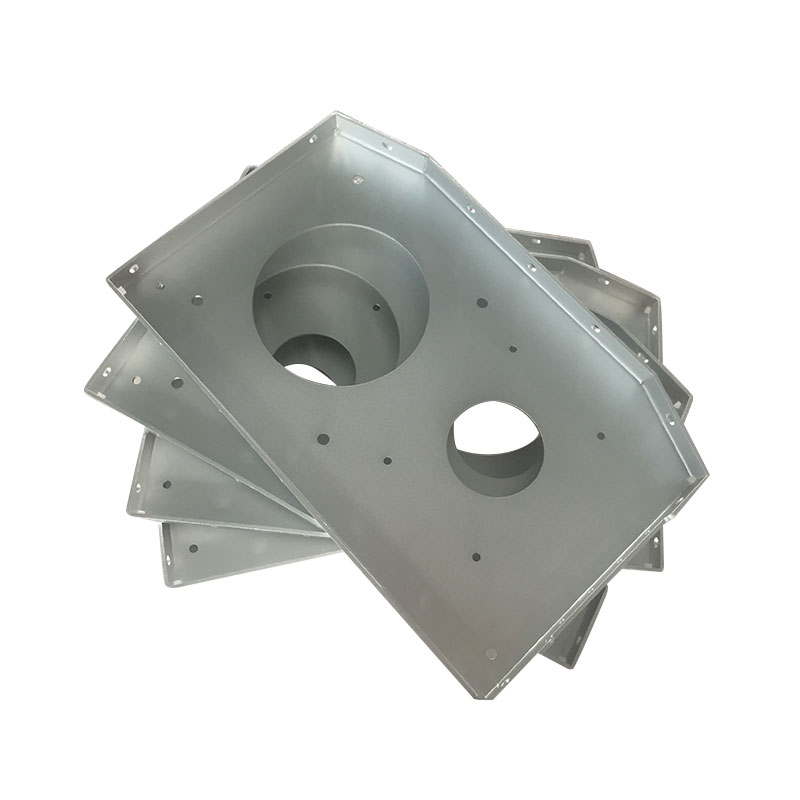

Laser Cutting Aluminium Sheet Metal Parts

To cut metal using a laser, a focused laser beam is directed at the material, which is then either melted, burned, vaporized, or blown away by a jet of gas. This cutting method leaves a sleek edge with high quality and a smooth finish.

Compared to mechanical cutting methods, a laser is easier to work with and there is a reduced possibility of contamination. Laser cutting is also more precise than mechanically cutting since the laser cannot wear down. Furthermore, since lasers use localized heat, there is less chance of warping.The following is about Laser Cutting Aluminium Sheet Metal Parts.

Aluminum Sheet Metal Fabrication

Aluminum is a very common metal utilized at Shbury to manufacture various OEM products for wide-ranging applications: on-highway vehicle doors/body panels, medical equipment, medical carts, energy dispensing stations, digital display, and variable messaging controls, consumer products, kiosks, various enclosures, and countless other parts. The following is about aluminum sheet metal fabrication.

Read MoreSend InquiryLow Volume Production Military Parts Vacuum Casting

Vacuum casting is a low-cost but reliable method for making a small number of high-quality prototypes based on a master model. This method is ideal for rapid prototyping used in engineering testing, proof-of-concept and display demos. On superior prototype, we have a dedicated team of mold makers who are experts at creating vacuum casting molds for many years.The following is about Low Volume Production Military Parts Vacuum Casting.

Read MoreSend InquiryMedical Device Plastic Housing Vacuum Casting

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about medical device plastic housing vacuum casting.

Medical Device Liquid Silicone Vacuum Casting Parts

In this era when user experience is highly valued, more and more manufacturers of mobile phones, laptops, and wearable devices are starting to make efforts in housing materials. In the mobile phone field alone, the material of mobile phone housing is also gradually moving from engineering plastic to metal.

But expensive metal will increase the budget if the design at the firstly stage, so the mobile phone manufacturer will use vauum casting to make the plastic housing to confirm the design before metal production.The following is about Medical Device Liquid Silicone Vacuum Casting Parts.