China Dental Instruments Components CNC Machining Manufacturers, Suppliers, Factory

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Dental Instruments Components CNC Machining,Dental Instruments Parts CNC Milling,Dental Instruments Products CNC Machining, Our main objectives are to deliver our clients worldwide with good quality, competitive cost, happy delivery and superb providers.

Dental Instruments Components CNC Machining, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We have been looking for the wholesale, Drop ship. Please contact us if you are interesting our items. Hope to do business with you all. High quality and fast shipment!

Hot Products

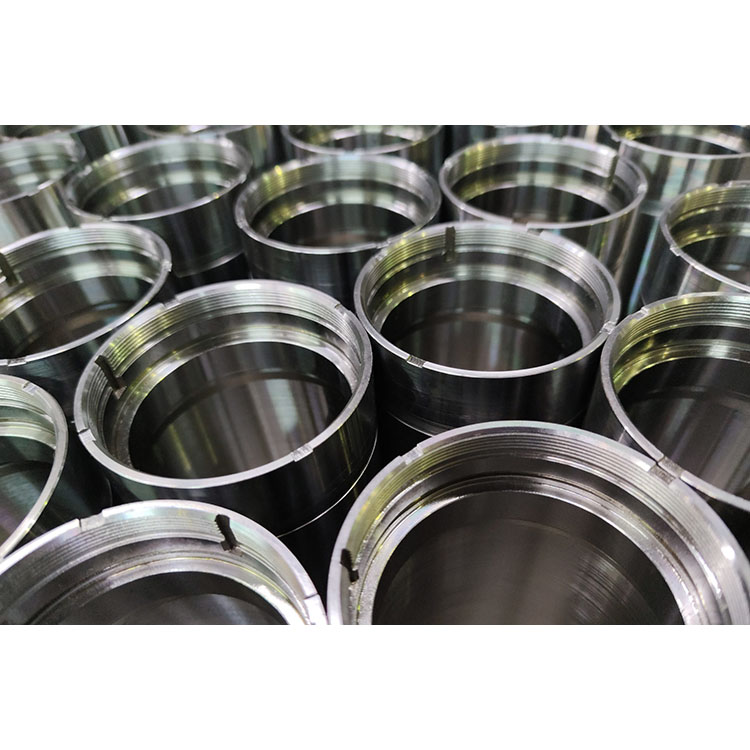

Aerospace Couplers Parts CNC Turning

Aerospace Couplers Parts CNC Turning Services With a view to produce superior products for customers, Shbury actively introduced advanced automatic machines. Currently there are several brand-new CNC automatic lathes, automatic secondary processors and other semi-automatic precise machines. Through the smooth operation of the qualified engineers, our products are more stable in quality and efficient of capacity. we are equipped with 10 precision CNC automatic lathes from Japan, as well as a series of precision measuring and QC inspection instruments. we are able to steadily improve technological know-how, lower defective rates, which already helped us to build a solid reputation.Aluminium Aerospace Parts CNC Machining

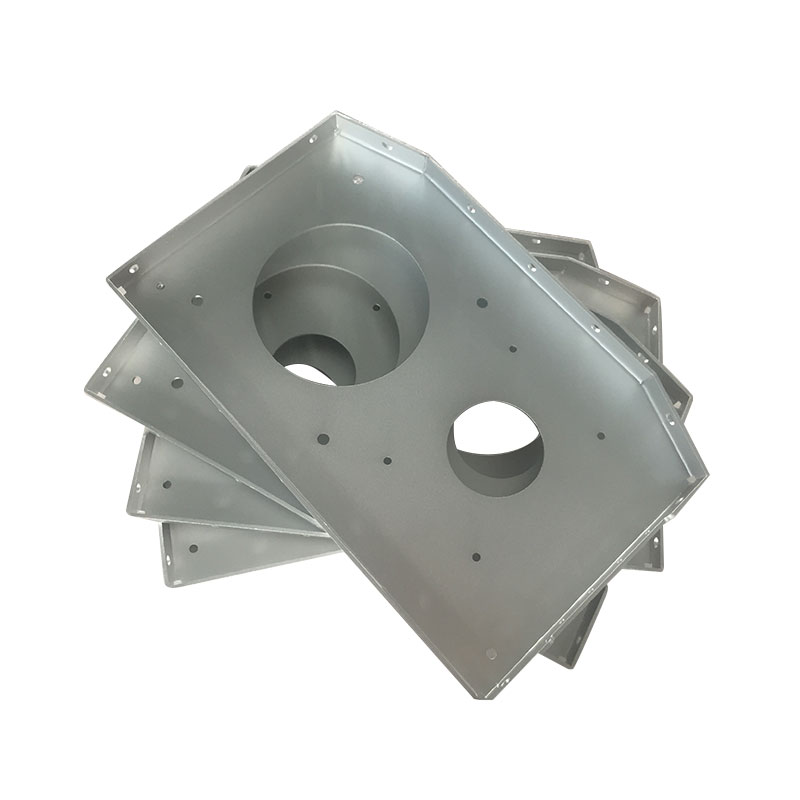

We have specialized skills and knowledge to aluminium aerospace parts CNC machining . We own advanced high-speed CNC machine tools to consistently maintain tight tolerances, produce end-use CNC machined aerospace components and aerospace prototypes to the highest precision in accordance with the requirements of our diverse customer base. Whether it is a high-volume order or a prototype project, we can always meet your exact requirements.Electronic Nozzle Products Cnc Turning

CNC aluminum tubes/pipe also known as the CNC machine nozzle, have the characteristics of corrosion resistance and lightweight, and are widely used in various industries, such as automobiles, aerospace, aviation, electronics industry, agriculture, electromechanical and so on. Aluminum pipes/tubes are ubiquitous in our life. But it’s most commonly used for shisha/hookah, tattoo or e-cigarette.The following is about Electronic Nozzle Products CNC Turning.Car Engine Housing Parts CNC Machining

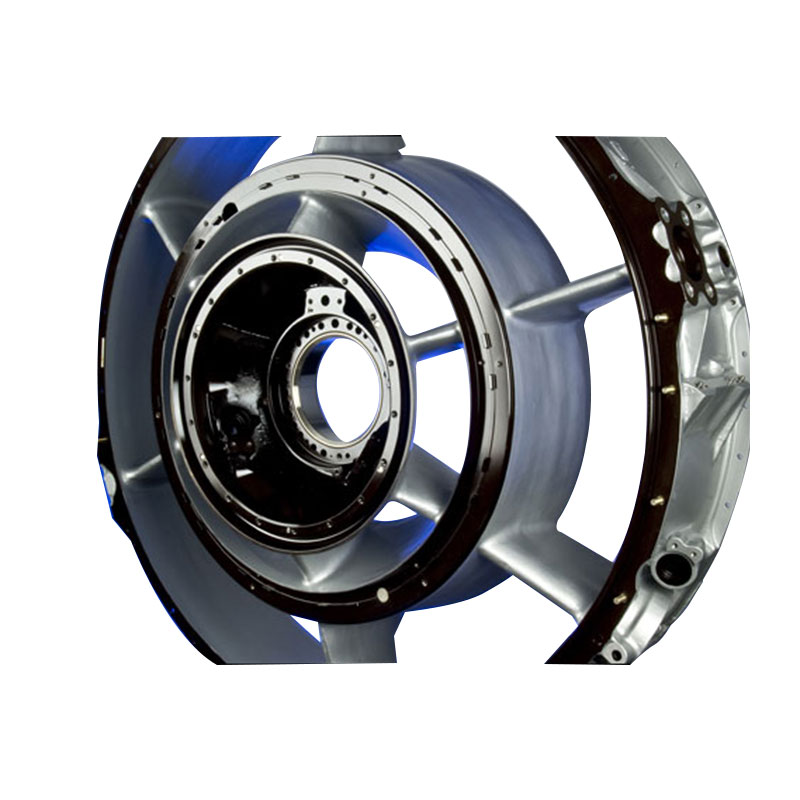

For some automotive components, CNC machining, which involves carrying out tasks like drilling and boring with computer control and automation, now serves as a favourable option for both prototyping and production.

CNC machines turn a digital file into a sequence computer instruction, which are sent to a motorised tool such as a drill, lathe or mill. The tool turns a block of material into a finished product by cutting it in the appropriate places, providing much greater accuracy than conventional machining.The following is about car engine housing parts CNC machining.Auto Track Hubs Frame Parts CNC Machining

Simple to complex part turning and milling machining services for Automotive industries. For automotive parts and parts machining,Shbury offers the highest degree of OEM service with a basis of 10+ years experience serving the automotive industry. Our automotive precision shop and experts deliver confidence. We have perfected the art of producing large component volumes with complete Shbury reliability, backed by the quality and long-term reliability our customers expect.The following is about auto track hubs frame parts CNC machining.Auto Oil And Gas Rubber Parts Vacuum Casting

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.The following is about Auto Oil And Gas Rubber Parts Vacuum Casting.