China Precision Aerospace Components CNC Machining Manufacturers, Suppliers, Factory

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for Precision Aerospace Components CNC Machining,Precision Aerospace Parts CNC Milling,Precision Aerospace Products CNC Machining, We give priority to good quality and customer fulfillment and for this we follow stringent excellent control measures. We've in-house testing facilities where our goods are tested on each and every aspect at different processing stages. Owning to latest technologies, we facilitate our prospects with custom-made production facility.

Precision Aerospace Components CNC Machining, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

Hot Products

Highest Level Military Parts Cnc Machining

CNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.Plastic Electronic Products Rapid Prototypes

Do you require quick, economic plastic prototypes with production-like material properties? Vacuum casting in silicone molds is the method that you need. Due to the low die costs, vacuum casting is particularly attractive as an economical secondary procedure for the reproduction of models in small batches.The following is about Plastic Electronic Products Rapid Prototypes.Mechanical Retainer Rings CNC Turning

The following is about Mechanical Retainer Rings CNC Turning.Aluminium Electronic Products Rapid Prototypes

Aluminum alloy is widely used in the industry. It is low in density, high in strength, excellent in elasticity, processability and welding characteristics. It also features good corrosion resistance, high toughness, and deformation after manufacturing.

Aluminum alloy molding can help discover potential flaws early in the product development stage, saving money in the long-run and minimizing production times. Aluminum alloy rapid prototype helps generate accurate product test data.The following is about Aluminium Electronic Products Rapid Prototypes.Medical X-ray Housing Rapid Prototypes

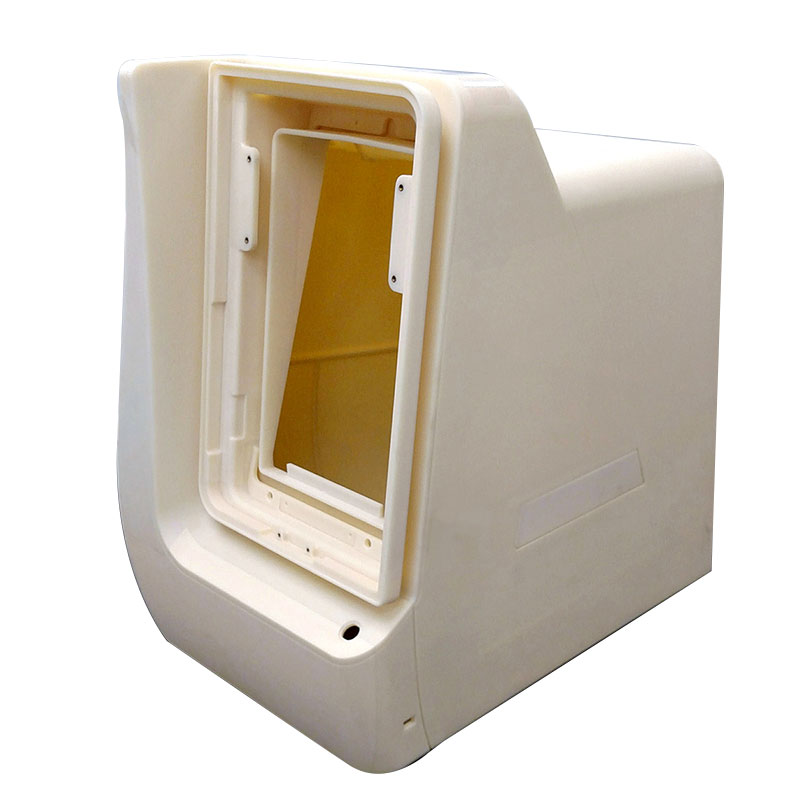

Optometry device cover for medical deviceThe design process for new or improved medical devices, such as catheters, stents, fluid administration systems, drug delivery systems, chemotherapy tips, syringes, cardio-vascular devices, vascular access devices, etc. includes the important step of producing, examining, and testing a physical medical prototype. Engineers and designers benefit from having a medical prototype to sample its size and get an idea of a its form, fit, and feel.The following is about Medical X-ray Housing Rapid Prototypes.Auto Flanges Fuser Rollers Parts CNC Turning

With the aid of our diligent professionals, we are engaged in manufacturing and supplying Turning Flange. These flanges are available for the clients in different sizes and specification. Precision turned from raw metal using high-end cnc machines, these flanges are provided to a large number of customers ranging from engineering to automotive industries Our offered flanges are quality tested with the aid of diligent analysts before the final dispatch. The Turning Flange is provided at the specified place on time.The following is about Auto Flanges Fuser Rollers Parts CNC Turning.