Galvanized Steel Sheet Metal Bending Parts

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication.

Send Inquiry

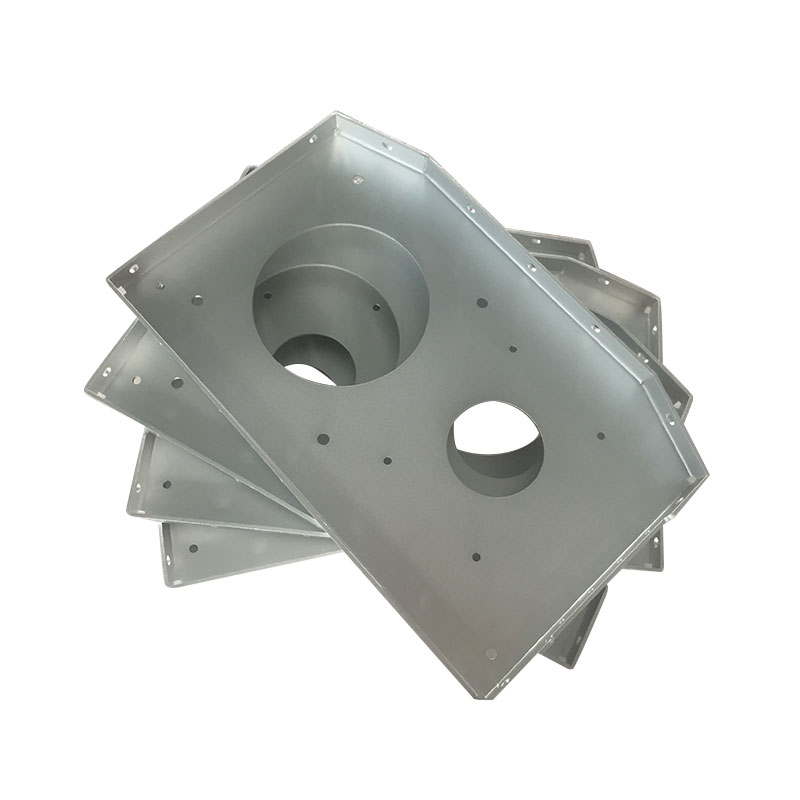

Galvanized Steel Sheet Metal Bending Parts

Galvanized steel sheet metal bending partsor galvanealed steel, which is galvanized then annealed.

Galvanization is the process of applying a protective zinc coating to steel in order to prevent rust and corrosion. Annealing is a heat treatment process that alters the microstructure of a material to change its mechanical or electrical properties, typically reducing the hardness and increasing the ductility for easier fabrication. We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for ODM Factory China Galvanized Steel Sheet Metal Bending Parts, Custom Sheet Metal Galvanized Stamping Bending Parts, Custom Manufacturing Metal Parts, Created items with brand worth. We attend seriously to produce and behave with integrity, and from the favor of buyers in your house and abroad from the ourindustry. ODM Factory China Galvanized Corrugated Sheet Meta, Custom Manufacturing Metal Parts, Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality goods and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

1.Product ParameterforGalvanized Steel Sheet Metal Bending Parts

Capacity

|

CNC Stamping |

1000 * 1000 mm(max) |

+/-0.05 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

Test Equipment |

measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

|

Thickness |

From 0.1 to 5mm |

|

Material Available

|

Stainless Steel |

SS201,SS301, SS303, SS304, SS316, SS416 17-4PH etc. |

|

Steel |

mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

|

Brass |

HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

|

Copper |

C11000,C12000,C12000 C36000 etc. |

|

Aluminum |

AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

|

Iron |

A36, 45#, 1213, 12L14, 1215 etc. |

Surface finish

|

Aluminum parts |

Stainless Steel parts |

Steel |

|

Clear Anodized |

Polishing |

Zinc plating |

|

Color Anodized |

Passivating |

Oxide black |

|

Sandblast Anodized |

Sandblasting |

Nickel plating |

|

Chemical Film |

Laser engraving |

Chrome plating |

|

Brushing |

|

Carburized |

|

Polishing |

|

Hot treatment |

|

Chroming |

|

Powder Coated |

2.Product Feature forGalvanized Steel Sheet Metal Bending Parts

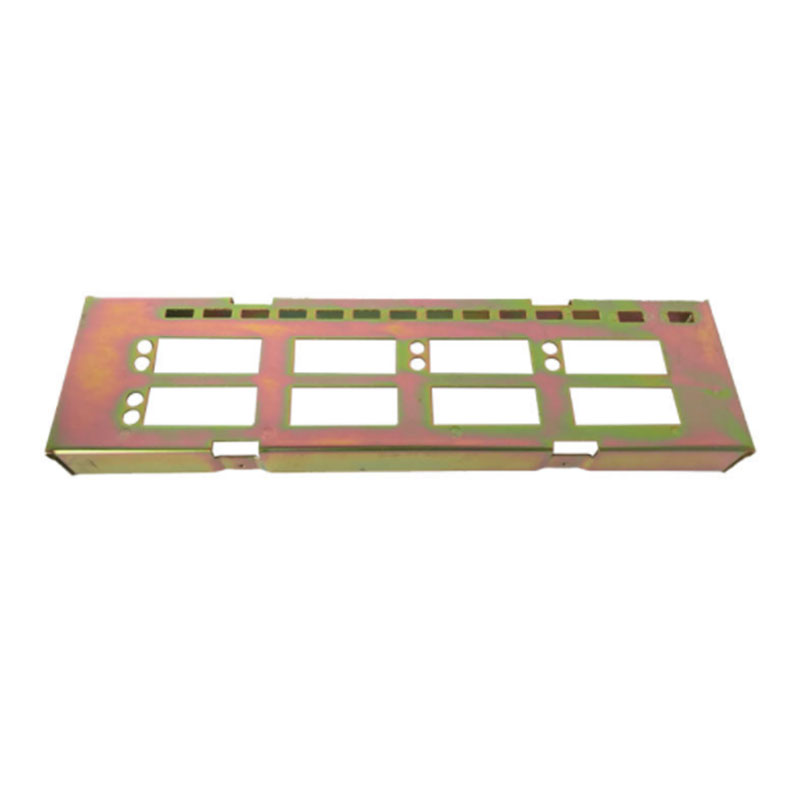

Material: Galvanized Sheet

Thickness: 2.5mm

Surface: industrial surface

Size: 1703mm*80mm*40mm

Tolerance: 0.5

Weight: 5.1kg

Process: laser cutting, bending

Application: water treatment equipment

3.Product Details forGalvanized Steel Sheet Metal Bending Parts

WhyGalvanized Steel Sheet Metal Bending Parts?

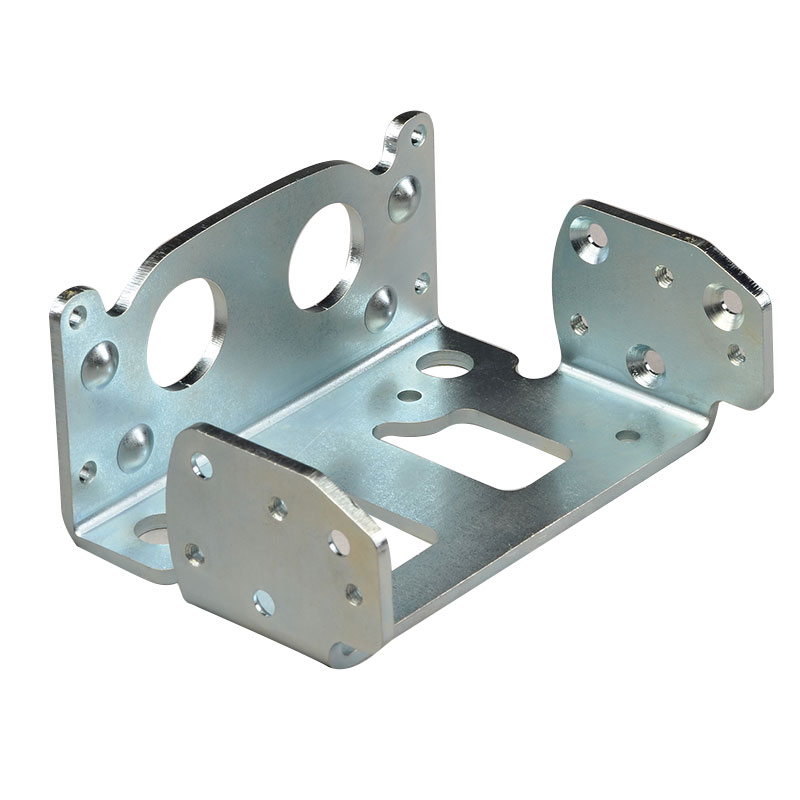

Depending on the application, sheet metal offers advantages, not just over non-metal alternatives but over other types of metal fabrication as well. Compared to machining, it generally has a significantly lower material cost.

Rather than starting with a block of material, much of which will be machined away, sheet metal lets you buy what you need and use what you need. The remainder of a metal sheet is still usable, while swarf—the shavings removed in machining—must be recycled.

4.Product Application forGalvanized Steel Sheet Metal Bending Parts

Sheet Metal

Parts are widely used, and almost all products that

can use metal parts can be used. Such as aerospace products, auto parts,

electronic products, mechanical equipment parts, medical equipment, defense and

military supplies.

5.FAQ

|

Q1:Where can I get product&price information? |

|

A1:Send us inquirye-mail, we will contact you as we receive your mail. |

|

Q2:How long can i get the sample? |

|

A2:Depends on your specific items,within 3-7 days is required generally. |

|

Q3:What's kinds of information you need for quote? |

|

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS, send the parts materials, quantity, surface finishing and other requirements to us as well. |

|

Q4: what's the payment terms? |

|

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance. |

|

For small amount, we also accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred |

|

Q5.Are you a trading company or factory? |

|

A5:We are direct factory with 10 experienced engineers and more than 30 employees as well approximate 3,000 square meters workshop area. |

|

Q6. What shall we do if we do not have drawings? |

|

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order. |

|

Q7. Can we get some samples before mass production? |

|

A7.Absolutely |

|

Q8. What is your MOQ? |

|

Our MOQ is 1pcs, it is also our one of advantage, even you have less budget, or want to reduce the risks before production, we both can accept the less MOQ. |

|

Q9: Will you do 100% inspection or random inspection ? |

|

We will do 100% inspection for samples, random inspection for mass production. When manufacturing, we will control the dimensions , do PQC in mass production. |

|

Q10. How to do if the parts not match with drawings we received? |

|

Contact us immediately, send the pictures and tell us the issues, we will check and repair or re-make the goods with free. |

|

Q11. You will how to ship the parts to me? |

|

When products finished, also passed by our QC, we will ship out the parts to you by DHL, Fedex , or by sea after communication |

6.Deliver,Shipping for Mobile Phone Housing Products Vacuum Casting